Innovations in the High Frequency Pipe Welding Machine sector are transforming the industry. Experts like Dr. Jane Miller highlight this shift, stating, "The future of welding lies in high frequency technology." Her insights capture the essence of current trends and advancements.

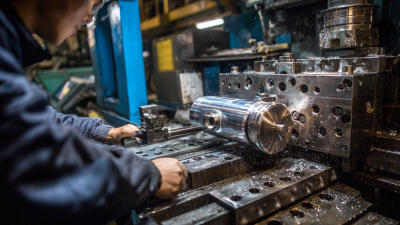

Current innovations are enhancing efficiency and precision. High frequency technology allows for faster welding cycles. Machines are becoming more automated, reducing human error. However, the industry faces challenges, such as high initial costs and training requirements for skilled operators.

As companies strive to adopt these innovations, they must weigh the benefits against potential drawbacks. Balancing technology with workforce needs is crucial. The landscape of High Frequency Pipe Welding Machines is evolving rapidly, presenting opportunities and obstacles alike.

The innovations in high frequency pipe welding technology for 2026 are set to be transformative. Developments focus on enhancing efficiency and precision. One notable trend is the integration of smart sensors. These sensors provide real-time data, allowing for better adjustments during welding. This proactive approach can reduce errors and improve overall quality.

Another trend is the exploration of new materials. As industries demand stronger and lighter pipes, traditional materials may no longer suffice. Advanced alloys and composites could become popular choices. However, the transition to these materials poses challenges in welding techniques. Training and adapting equipment can take time.

Sustainability is also at the forefront. Many companies are seeking eco-friendly methods for their welding processes. Reducing energy consumption is a focus area. Yet, not all innovations have clear solutions. Experimentation may lead to setbacks. Manufacturers must stay patient and adaptable in this evolving landscape.

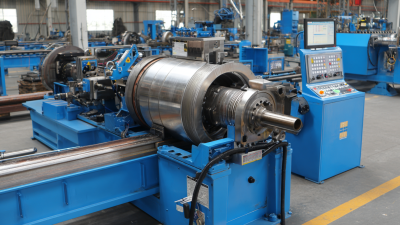

High frequency pipe welding machines are evolving rapidly. The demand for efficiency drives innovations. Users seek faster and more precise welding processes. These machines are increasingly automated. Automation reduces labor costs and boosts productivity. New technologies allow for better control of welding parameters. This results in stronger, more durable welds.

Moreover, sustainability trends are influencing machine designs. Energy-efficient systems attract attention. Manufacturers focus on reducing waste during the welding process. Using eco-friendly materials is also becoming common. However, not all innovations are perfect. Some machines may struggle with consistency. This affects the overall quality. Feedback from users highlights areas for improvement. Ongoing developments address these shortcomings, ensuring better performance.

As the industry progresses, safety remains a key concern. Machines incorporate advanced safety features. However, training for operators is crucial. Understanding these systems can prevent accidents. The balance between speed and safety is a challenge. Engaging with emerging technologies is essential, yet reflection on their impacts is necessary. Continuous improvement is the goal, but the journey has bumps along the way.

High frequency pipe welding machines are evolving rapidly. These machines are now equipped with advanced control systems. This means better precision in welding processes. Users can expect faster setups and improved reliability. Some machines offer real-time feedback, allowing operators to adjust settings instantly.

A key feature is automation. Many machines now integrate automated feeding systems. This reduces manual labor and minimizes errors during operation. Additionally, there is an emphasis on energy efficiency. New models consume less power while maintaining high performance. This is a win-win for cost savings and environmental impact.

However, the rise of automation raises concerns. There is a potential skill gap in the workforce. Operators may need training to manage these advanced machines. Some traditional techniques may be overlooked. It’s essential to find a balance between innovation and preserving craftsmanship in welding.

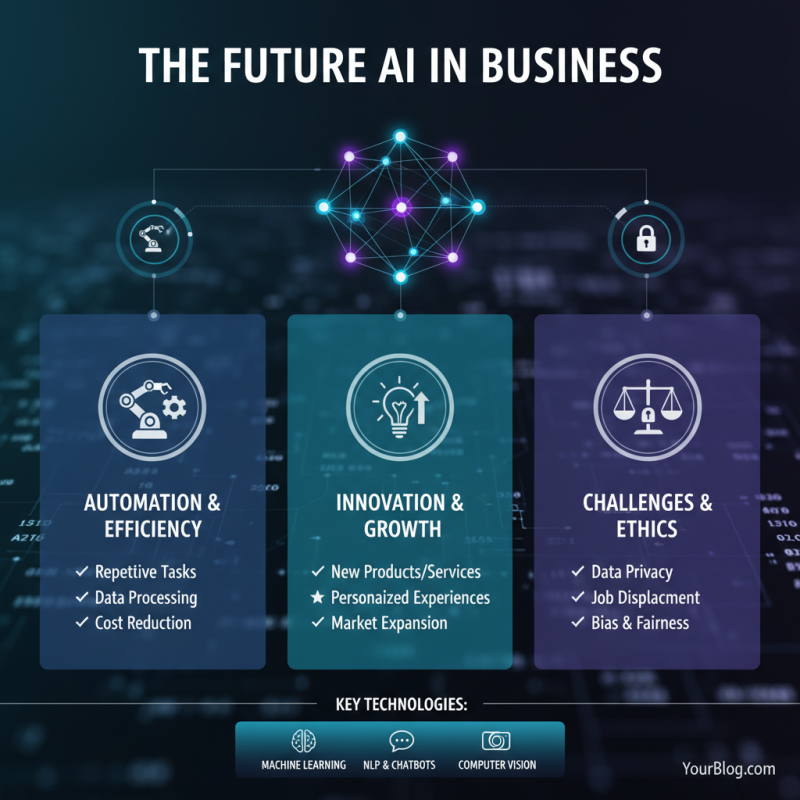

Automation and AI are transforming pipe welding. These technologies enhance precision and efficiency. They reduce human error and speed up the process. Automation systems can handle repetitive tasks. This allows skilled workers to focus on complex challenges. The integration of AI provides real-time data analysis. Welding machines can adapt to varying conditions on the fly.

Tips: Regular training for your team is essential. They need to understand these new technologies. Continuous learning keeps skills up to date.

Visualizing the workspace is vital. A well-organized area boosts productivity. Ensure that tools and machines are easily accessible. It minimizes wasted time. Not every automated system is flawless. Companies must be open to feedback for improvements. Monitoring and adjusting processes lead to better outcomes.

The welding industry is evolving rapidly. A recent report suggests that the global advanced welding machine market is projected to reach $10.5 billion by 2027. This growth is driven by innovations in high-frequency welding technologies. The demand for durable and precise welding applications in sectors like construction and automotive is on the rise.

Advanced welding machines now incorporate features like automation and data analytics. These technologies enhance precision and reduce waste. However, integration remains a challenge for many companies. Training staff to operate new machines requires time and investment. Some businesses struggle with adapting to these rapid changes. The path to innovation is not always smooth.

Future applications seem promising. Industries are exploring robotic welding and hybrid techniques. These innovations may lead to improved efficiency and reduced operational costs. Yet, companies need to assess their readiness to adopt these advancements. Industry surveys show that 45% of businesses feel unprepared for such changes. Understanding market potential is crucial for successful implementation.