In the ever-evolving manufacturing landscape, the demand for efficient and high-quality Tube Mill Making Machines has surged significantly. According to a recent report by the Global Manufacturing Technology Association, the market for tube mills is projected to grow at a CAGR of 7.5% from 2023 to 2030, highlighting the increasing reliance on these machines for producing precision-engineered tubes in various industries, including construction, automotive, and energy.

However, despite advancements in technology, manufacturers struggle with several critical issues related to these machines, including operational efficiency, maintenance costs, and output quality. As businesses strive to meet growing consumer demands while navigating challenges such as rising raw material costs and supply chain disruptions, identifying the best Tube Mill Making Machine becomes paramount.

This blog will explore the salient problems facing contemporary tube mills and present insights on selecting the optimal machine to enhance productivity and ensure sustainability in manufacturing operations.

The evolution of tube mill making machines has been a significant topic in modern manufacturing, reflecting technological advancements and changing industry demands. Traditionally, tube mills were largely mechanical devices with limited capabilities, but today’s machines incorporate sophisticated automation and precision engineering. According to a report by MarketsandMarkets, the global tube and pipe manufacturing market is projected to reach USD 1.1 billion by 2025, driven by increased demand for high-performance materials in various sectors, including construction and automotive.

Moreover, the integration of Industry 4.0 technologies, such as IoT and AI, has revolutionized tube mill operations. Modern machines are now equipped with real-time monitoring systems that enable predictive maintenance, ultimately reducing downtime and improving productivity. A study by Allied Market Research indicates that the adoption of smart manufacturing techniques could increase efficiency by up to 30%. This shift not only enhances production capabilities but also allows manufacturers to produce of higher quality tubes that meet stringent industry standards, signifying a remarkable transformation in the tube making industry.

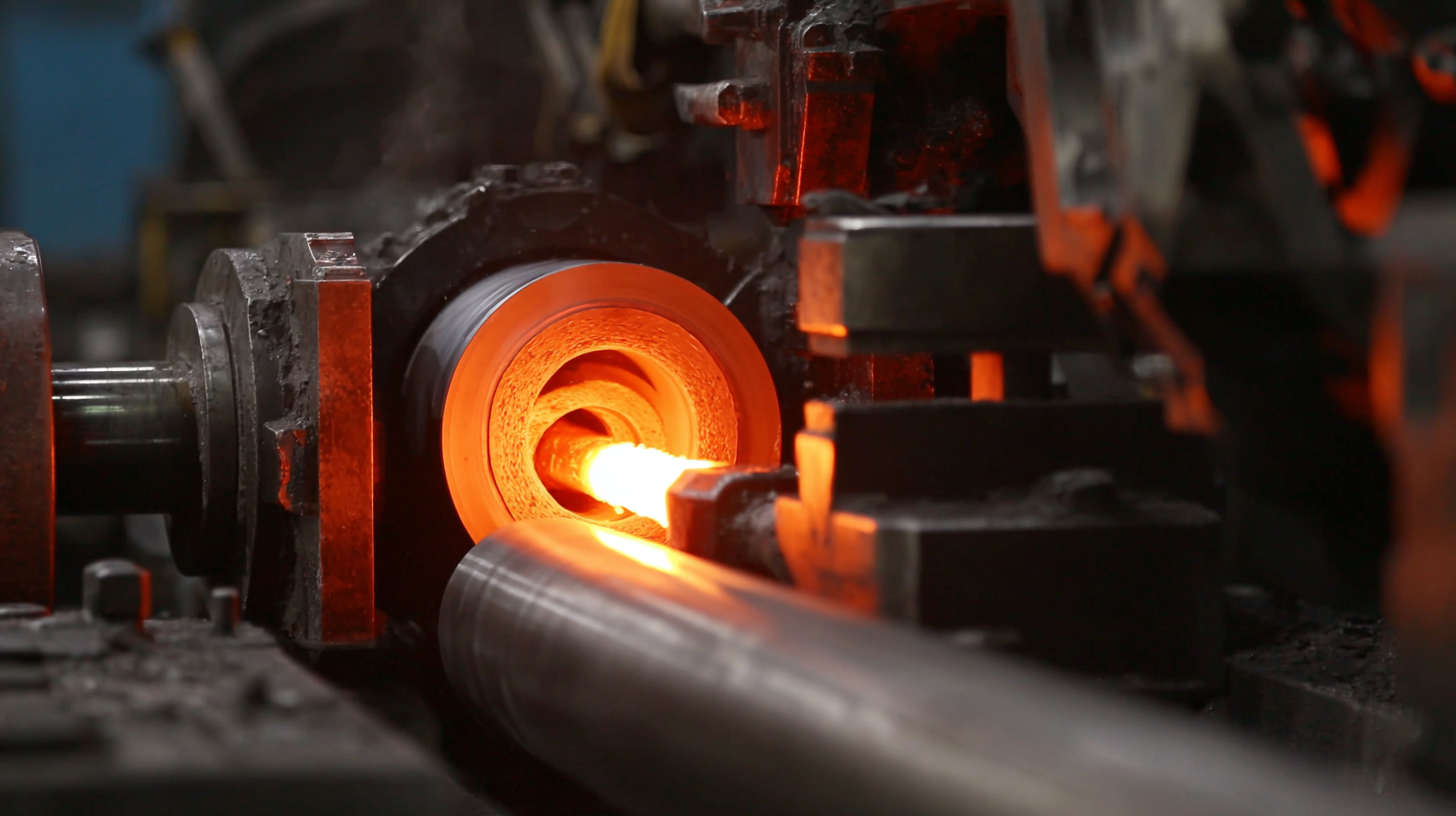

When evaluating the best tube mill making machine in the modern manufacturing industry, several key features stand out as essential for ensuring quality and efficiency. First, a robust and reliable drive system is crucial. It should offer variable speed control, which allows for flexibility in production processes, accommodating different material specifications and tube dimensions. Additionally, the machine should have high precision alignment capabilities, which minimizes errors and waste while producing uniform tubes.

Another important feature to consider is the quality of the materials used in the machine's construction. A top-quality tube mill should be made with durable components that can withstand the wear and tear of continuous operation. Look for machines with high-grade steel frames and cutting-edge technology that enhances durability and minimizes maintenance requirements. Lastly, advanced automation features can significantly improve the overall productivity of the machine. Systems that enable real-time monitoring and adjustments can lead to better performance, reduced downtime, and an increased return on investment in the long run.

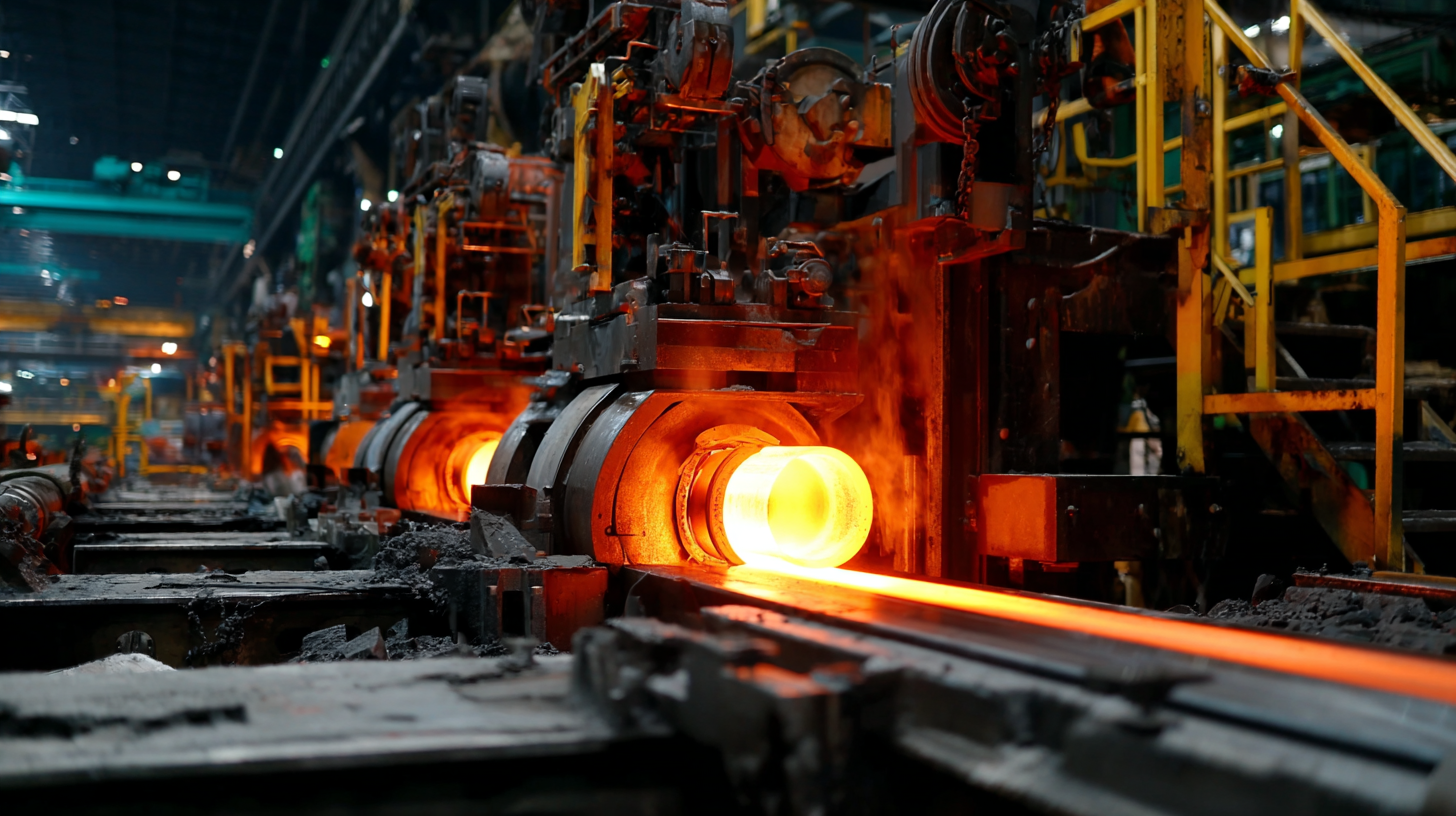

The modern manufacturing industry is experiencing a significant transformation, particularly in the realm of

tube mill production, where automation and advanced technology play pivotal roles. Recent reports indicate a growing demand for

copper tubes, with the processing and manufacturing sectors rapidly expanding. This surge can be attributed to the enhanced efficiencies brought by automated systems, which streamline production processes, reduce labor costs, and improve product quality. As a result, manufacturers are increasingly adopting

cutting-edge tube mill making machines that integrate sophisticated technology to meet the rising market needs.

Furthermore, innovations in rolling technology and continuous rolling automation are setting new industry standards. Institutions dedicated to advancing these technologies are also emerging, focusing on research and development to facilitate this shift. With such advancements, tube mills can produce a more diverse range of products tailored to specific applications, thereby boosting overall productivity. This evolution reflects the broader industry trend towards

smart manufacturing, where data-driven approaches and connectivity enable manufacturers to adapt swiftly to changing demands, ensuring their competitive edge in an increasingly dynamic marketplace.

The tube mill manufacturing industry is undergoing significant transformations as sustainability emerges as a paramount trend leading into 2025. As manufacturers strive to reduce their environmental impact, innovative techniques and materials are being adopted in tube mill operations. This shift not only aligns with global sustainability goals but also responds to rising consumer demand for eco-friendly products. Companies are investing in efficient machinery that minimizes waste and uses renewable resources, paving the way for a greener manufacturing ecosystem.

Furthermore, the stainless steel seamless pipes market, projected to reach USD 5.15 billion by 2030, exemplifies the synergy between sustainability and market growth. The manufacturing processes are evolving to incorporate recycled materials and energy-efficient methods, contributing to the overall reduction of carbon footprints in tube mill production. As regulatory pressures increase and consumers become more environmentally conscious, tube mill manufacturers are positioned to lead the way in sustainable practices, setting benchmarks for other sectors within the industry.

| Data Dimension | 2023 | 2024 (Projected) | 2025 (Projected) |

|---|---|---|---|

| Revenue from Tube Mill Machines (in Million USD) | 1500 | 1650 | 1800 |

| Sustainable Material Usage (%) | 30 | 40 | 50 |

| Energy Consumption (kWh per unit produced) | 120 | 110 | 100 |

| Carbon Emissions (kg per unit produced) | 15 | 12 | 10 |

| Percentage of Recycled Materials Used (%) | 20 | 25 | 30 |

The future of tube mill machines in the manufacturing industry is poised for significant transformation driven by advancements in digital manufacturing technologies. As industries embrace automation and smart technologies, tube mill machines are becoming more efficient, adaptable, and capable of producing higher-quality products. These innovations enhance productivity by minimizing downtime and optimizing operational workflows. The incorporation of Industry 4.0 principles, such as artificial intelligence and machine learning, allows for real-time monitoring of production processes, leading to better decision-making and increased output.

Moreover, as the global manufacturing landscape evolves, the integration of specific systems that utilize data analytics is becoming essential. This will enable manufacturers to anticipate maintenance needs, reduce waste, and improve the overall sustainability of their operations. As the trends of customization and flexibility take center stage, future tube mill machines will be designed to accommodate diverse product configurations, making them indispensable in the highly competitive manufacturing sector. Such adaptations promise to set new benchmarks for efficiency and innovation, solidifying the role of tube mill machines in the modern age.