In the rapidly evolving landscape of manufacturing, Custom Tube Mill Pipe Making Machinery has become a cornerstone for industries seeking efficiency and precision. According to a recent report by Market Research Future, the global pipe manufacturing market is set to reach a value of over $15 billion by 2025, driven by increasing demands in sectors such as construction and automotive. This growing demand underscores the necessity for high-quality machinery that can produce seamless and robust pipe solutions. As businesses strive to enhance their operational capabilities, identifying reliable suppliers of Custom Tube Mill Pipe Making Machinery is crucial for ensuring the sustainability and competitiveness of their products in the global market. This blog will explore effective strategies for finding top-tier suppliers that meet the rigorous standards of quality and innovation that define the industry.

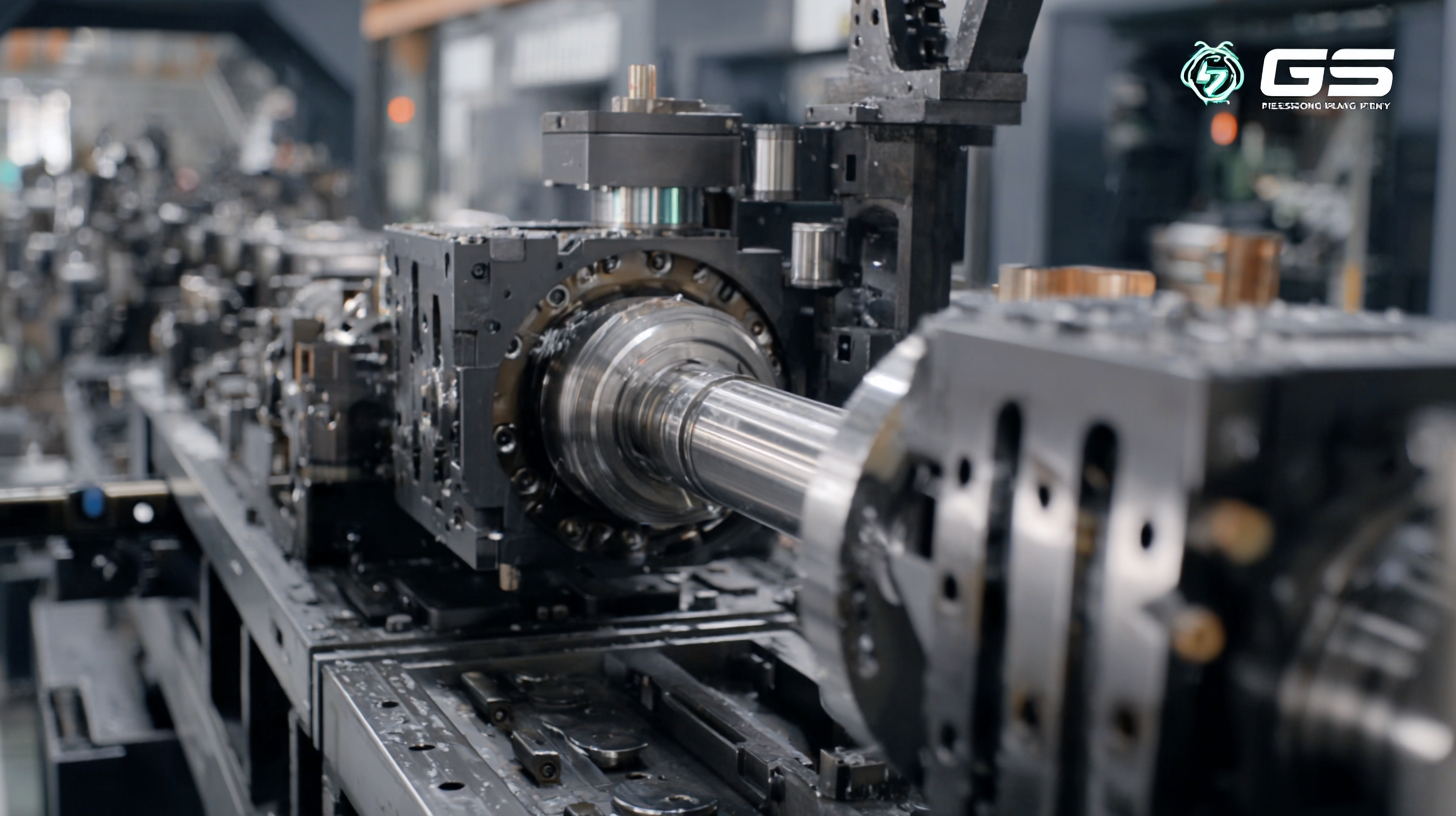

The evolution of custom tube mill technology in China is a remarkable journey marked by innovation and precision. Over the past two decades, China has emerged as a leading player in the global tube and pipe manufacturing industry, with a share of nearly 36% of the world market, according to recent industry reports. The advancement in custom tube mill machinery has been propelled by significant investments in research and development, enabling manufacturers to produce high-quality tubes that meet international standards.

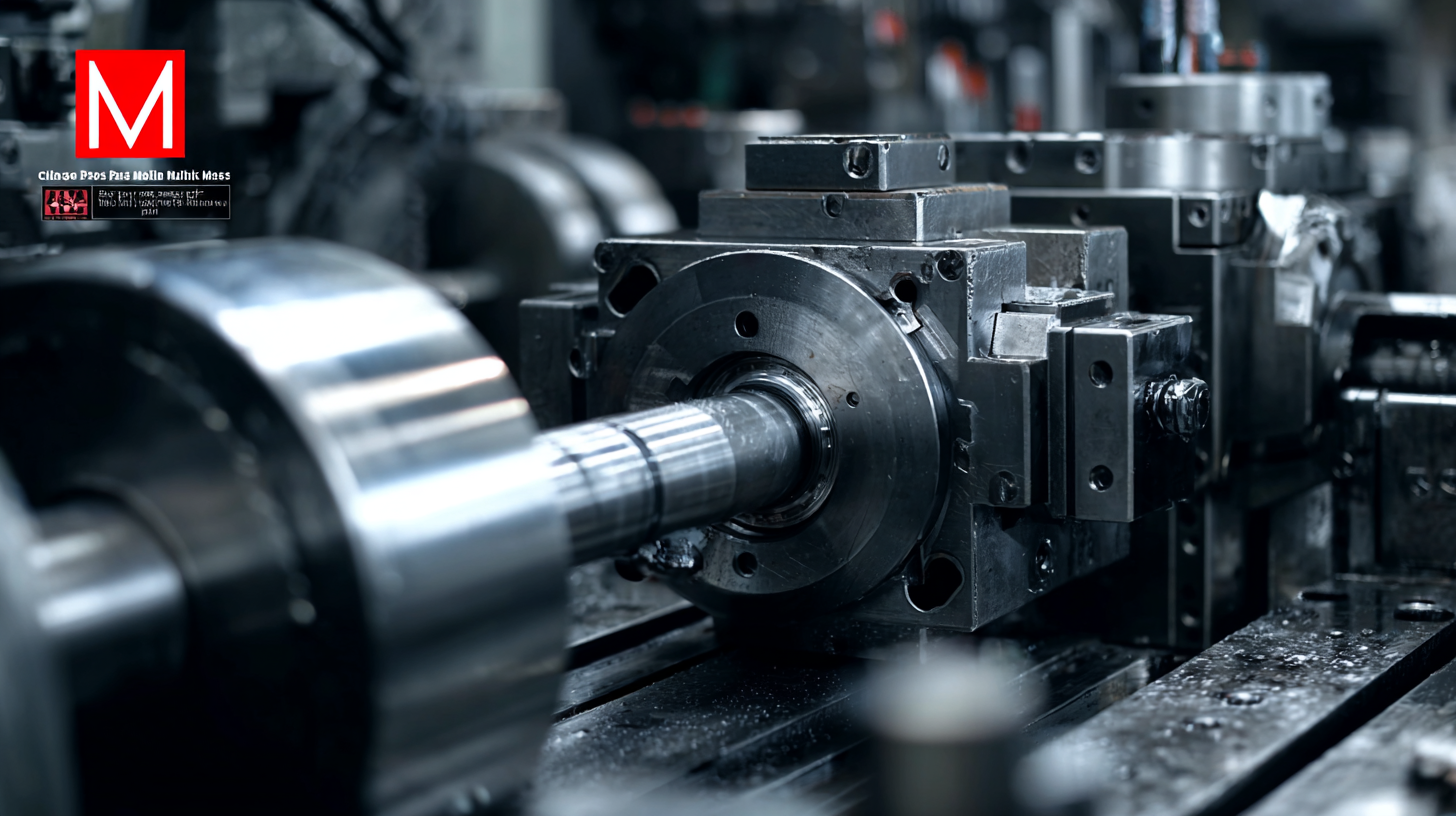

One key area of development is the integration of automated systems within custom tube mills. Modern machinery now employs advanced software for precision control and enhanced efficiency, which allows manufacturers to reduce production times by up to 25%. Moreover, the shift towards environmentally friendly practices has led to the development of energy-efficient machines that consume 30% less power compared to traditional models. This focus on sustainability not only benefits the bottom line but also enhances the reputation of Chinese manufacturers on a global scale. The combination of technological prowess and commitment to quality positions China as a formidable leader in the custom tube mill industry, continually earning respect worldwide.

When it comes to tube mill pipe making machinery, Chinese manufacturers have set themselves apart on the global stage with their remarkable innovations and competitive pricing. Among the key features that differentiate Chinese tube mills from their competitors are advanced automation, energy efficiency, and robust construction quality. These attributes not only enhance production efficiency but also significantly reduce operational costs, making them a preferred choice for manufacturers worldwide.

Tip: When selecting a tube mill, always consider the level of automation offered. High automation can lead to less downtime and increased productivity. Additionally, look for energy-efficient models that can save on electricity costs over the long run.

Moreover, Chinese tube mills often incorporate cutting-edge technology, such as digital monitoring systems and smart manufacturing capabilities. These innovations allow for real-time performance tracking and maintenance scheduling, thereby increasing the lifespan of the equipment.

Tip: Prioritize equipment that includes smart features, as they can improve management of resources and minimize waste in your production line. Always request detailed specifications to ensure the machinery aligns with your operational needs.

The global applications of Chinese pipe making machinery are increasingly prominent as these advanced technologies gain recognition for their efficiency and innovation. Industries across various sectors are capitalizing on the high-quality production capabilities offered by premier custom tube mill machinery. The integration of these machines into production processes not only boosts output but also ensures precision, catering to diverse market needs. This comparative analysis highlights the competitive edge that China holds in the pipe manufacturing landscape, underpinned by a commitment to research and development.

Moreover, the demand for biogas solutions presents another avenue where Chinese machinery contributes significantly. The growing emphasis on renewable energy has led to an uptick in the production and utilization of biogas, which is derived from organic materials. The technology implemented in manufacturing pipes for biogas applications is tailored to withstand the specific demands of the industry, ensuring durability and efficiency. As the market expands, the collaboration between innovative machinery and sustainable energy initiatives exemplifies a global respect for Chinese manufacturing prowess, positioning it as a leader in both productivity and sustainability.

China has made remarkable strides in tube mill manufacturing, setting a high bar in quality standards that garner global respect. The nation’s ability to produce custom tube mill pipe making machinery with precision has not only attracted international clients but also positioned China as a leader in the industry. Reports indicate that over 40% of the world’s steel pipe production now comes from China, illustrating its dominance. High standards in manufacturing protocols, coupled with continuous innovation, enable Chinese manufacturers to meet the diverse needs of the global marketplace.

Tips for ensuring quality in tube mill manufacturing include investing in advanced technology, such as automated inspection systems, which significantly enhance production accuracy. Maintaining strict adherence to international quality certifications can also boost a manufacturer’s credibility. Moreover, collaboration with industry experts to fine-tune production processes can lead to improvements in both output and efficiency.

The recent focus on national security and tariffs on steel imports in the United States has further amplified the need for high-quality domestic manufacturing. As companies navigate these challenges, the competitiveness of their products heavily relies on their adherence to quality standards. By taking cues from Chinese manufacturing practices, firms can strive for excellence in their operations while aligning with global best practices.

The custom tube mill industry is undergoing a transformative phase, driven by rapid advancements in technology and evolving market demands. Innovation stands at the core of this evolution, as manufacturers adopt automation, smarter production lines, and enhanced material processing techniques. These advancements not only improve efficiency and reduce waste but also enable companies to customize products to meet specific customer requirements, a crucial factor in today’s competitive landscape.

Moreover, global market trends indicate a shift towards sustainability, pushing producers to develop environmentally-friendly manufacturing processes. As eco-consciousness rises among consumers and businesses alike, custom tube mill solutions that emphasize energy efficiency and minimal environmental impact are becoming increasingly desirable. This focus on sustainability, combined with technological improvements, positions custom tube mills as a vital component in sectors spanning construction to automotive, ultimately paving the way for substantial growth in the international market.