In the world of manufacturing, the choice of machinery can significantly impact production efficiency and product quality. Among the various options available, the "Round Pipes Machine" stands out as a versatile and essential tool for companies specializing in pipe production. This innovative equipment is designed to streamline the manufacturing process, providing businesses with the ability to produce high-quality round pipes in various sizes and specifications.

The advantages of utilizing a Round Pipes Machine extend beyond mere production capabilities. These machines are engineered to optimize operational performance, minimize waste, and reduce labor costs, making them an attractive investment for manufacturers aiming to enhance profitability. Furthermore, with advancements in technology, modern Round Pipes Machines offer features such as automated controls and precision engineering, ensuring consistent results and improved product reliability.

In an increasingly competitive market, selecting the right machinery is crucial for maintaining a competitive edge. By embracing the benefits of a Round Pipes Machine, manufacturers can not only meet the demands of their clients but also position themselves for future growth and innovation in the industry.

Round pipe machines are essential tools in various manufacturing sectors, known for their versatility and efficiency in producing round pipes with precise specifications. These machines function by using advanced technology to shape raw materials into desired pipe dimensions, allowing manufacturers to meet increasing demands. Understanding the functionality of round pipes machines is crucial for businesses looking to enhance their production line and reduce waste. The key components of these machines include cutting, bending, and welding systems, all working in unison to create high-quality pipes.

When considering a round pipes machine for your operations, it’s important to assess the technology and capabilities it offers. Look for features such as automation options, which can significantly increase production efficiency by minimizing human error. Additionally, consider the machine's versatility in handling various materials, as this can lead to more diverse product offerings.

Tips: Regular maintenance of your round pipe machine is essential for optimal performance. Schedule routine checks and ensure that all parts are functioning properly to avoid costly downtimes. Moreover, invest in training for your operators to maximize the machine's capabilities and ensure safety protocols are followed. Continuous learning about advancements in round pipe technology can also provide you with a competitive edge in the market.

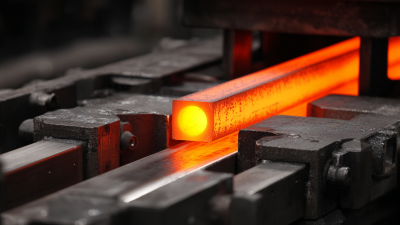

When it comes to manufacturing, the use of round pipe machines offers significant advantages that can enhance efficiency and productivity. One of the primary benefits of employing round pipe machines is their ability to produce uniform and high-quality pipes consistently. This is crucial for industries that require precision in their components. The automated processes in these machines reduce the likelihood of human error, ensuring that each pipe maintains the same specifications, which is essential for downstream processes and final product reliability.

Another key advantage is the versatility these machines provide. Round pipe machines can be used to work with a variety of materials, including metals and plastics, making them suitable for a wide range of applications. This adaptability allows manufacturers to meet diverse demands without needing multiple machines for different materials. Furthermore, the machines typically feature programmable settings, enabling quick adjustments for different pipe sizes, which streamlines production and reduces downtime.

The overall efficiency gained from using round pipe machines not only improves the manufacturing timeline but also enhances the capability to respond to market changes swiftly.

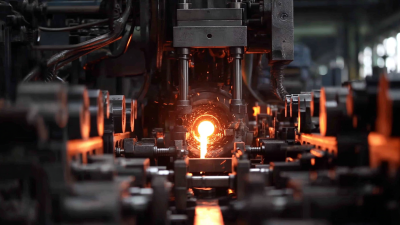

When it comes to manufacturing pipes, the choice of equipment can significantly affect both productivity and product quality. Round pipes machines stand out among various pipe manufacturing equipment due to their efficiency and versatility. Industry reports indicate that round pipes account for approximately 40% of the global pipe market, reflecting their importance in various applications, including construction, plumbing, and energy sectors. These machines are designed to produce high-dimensional accuracy and surface quality, making them suitable for demanding projects.

Comparatively, round pipes machines often outperform other types of pipe manufacturing equipment, such as square or rectangular pipes machines, in terms of production speed and waste reduction. Data suggests that round pipes machines can increase production efficiency by up to 25% when processing standardized materials. This can lead to significant cost savings over time, especially in high-volume manufacturing environments. The streamlined design of round pipes means they require less machining and finishing, allowing manufacturers to allocate resources more effectively.

**Tips:** When selecting a round pipes machine, consider the specific types of materials you will be working with and the required output sizes. Additionally, integrating automation into your manufacturing process can further enhance efficiency and precision. Investing in high-quality machinery can also reduce long-term operational costs through improved durability and decreased maintenance needs.

Round pipes have become essential components in a wide range of industries due to their versatile applications. In the construction sector, round pipes are commonly used for framing structures, plumbing systems, and HVAC installations. Their circular shape provides strength and stability, making them ideal for bearing heavy loads and withstanding high pressure. Additionally, in the automotive industry, round pipes are crucial for exhaust systems and safety features, where durability and efficiency are key.

In the manufacturing sector, the ease of handling and processing round pipes makes them a popular choice for producers. These pipes can be easily welded, bent, and joined, facilitating the creation of complex assemblies. Moreover, round pipes are utilized in agricultural applications for irrigation systems and greenhouse support structures, emphasizing their importance in ensuring efficient resource management.

**Tips**: When selecting round pipes for your production needs, consider the material properties that best suit your application—be it stainless steel for corrosion resistance, or aluminum for lightweight needs. Always ensure you have the right tools and machinery for precise cuts and fittings to maintain the integrity of your project. Additionally, evaluating the long-term performance of different materials will help in making an informed decision that aligns with sustainability goals.

| Industry | Application | Material Used | Benefits of Round Pipes |

|---|---|---|---|

| Construction | Structural support | Steel, Aluminum | High strength, durability |

| Automotive | Exhaust systems | Stainless steel | Corrosion resistance, lightweight |

| Oil & Gas | Pipeline construction | Carbon steel | High pressure tolerance, reliability |

| Agriculture | Irrigation systems | PVC, HDPE | Lightweight, flexibility |

| Manufacturing | Robotic arms | Aluminum, Titanium | Strong, lightweight design |

When selecting a round pipes machine for your manufacturing needs, several key factors must be considered to ensure optimal productivity and efficiency. First and foremost, evaluate the machine’s capacity and specifications. The throughput rate and the diameter range of the pipes will significantly influence your production capabilities. Ensuring that the machine can handle the specific sizes and quantities you require is essential for meeting your operational demands.

Additionally, consider the technology and features integrated into the machine. Advanced machines often come equipped with automation capabilities, enhancing precision and reducing labor costs. Features such as programmable settings can facilitate the production of various pipe specifications while maintaining consistent quality. Furthermore, examining the ease of maintenance and availability of technical support is crucial, as these aspects can significantly affect long-term operational efficiency. Prioritizing a machine that combines reliable performance with user-friendly features will contribute to a smoother production process and sustained manufacturing success.