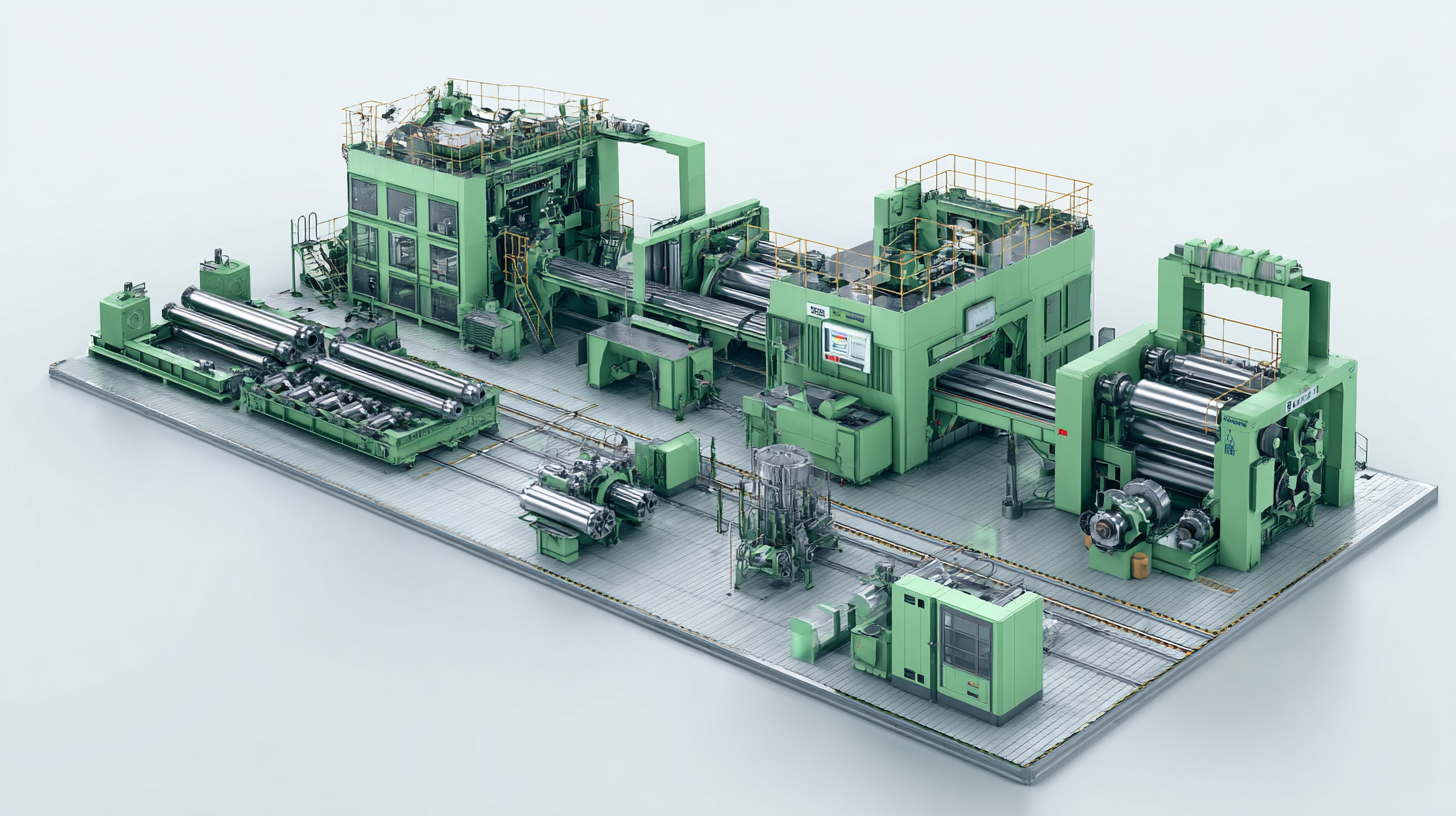

In the competitive landscape of the pipe manufacturing industry, optimizing production efficiency is paramount for manufacturers utilizing Pipe Making Machinery Tube Mill technology. According to a recent report by Grand View Research, the global steel pipe market is expected to reach USD 293.3 billion by 2025, growing at a CAGR of 5.6%. This surge in demand underscores the necessity for robust and efficient machinery to streamline production processes. As manufacturers strive to meet growing market needs, focusing on optimization can lead to substantial gains in productivity and profitability. Implementing effective strategies not only enhances the operational performance of tube mills but also minimizes waste and boosts overall output. In this blog, we will explore seven essential tips for optimizing your Pipe Making Machinery Tube Mill production, ensuring you can capitalize on market opportunities while maintaining high quality standards.

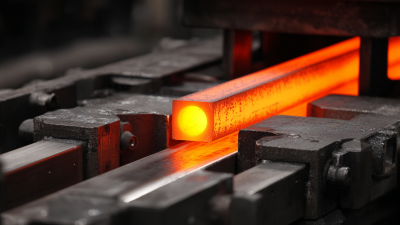

In the world of pipe making, understanding the fundamental operations of tube mills is crucial for maximizing productivity. Tube mills, which are designed to produce welded or seamless pipes, must be optimized at every stage of the production process. Recent studies indicate that companies investing in advanced tube mill technology can improve efficiency by as much as 25%, highlighting the importance of staying updated with industry innovations.

To enhance productivity, one essential tip is to regularly maintain and calibrate machinery to prevent downtime. According to the International Tube Association, equipment failure can lead to production losses of over 15%. Implementing a strict maintenance schedule can mitigate such risks. Additionally, optimizing setup times on tube mills can significantly reduce cycle times. Lean manufacturing principles recommend evaluating and streamlining workflows, which can lead to a productivity increase of approximately 20%.

Furthermore, employing data analytics can provide insights into operational bottlenecks. By analyzing production metrics, manufacturers can make informed decisions that improve overall throughput. A report by the American Institute of Steel Construction suggests that data-driven operations have the potential to enhance production rates by up to 30%. Embracing these strategies not only boosts efficiency but also positions your business ahead in a competitive market.

This chart illustrates key metrics for optimizing tube mill production. The focus is on speed, efficiency, downtime, scrap rate, and maintenance costs as crucial factors to enhance productivity in pipe making machinery.

To ensure your pipe making machinery operates at peak efficiency, implementing key maintenance practices is vital. Regular inspections of the tube mill can help identify potential issues before they escalate. Schedule routine checks on components such as rollers, welders, and motors. By staying proactive, you can minimize downtime and enhance productivity.

In the realm of tube mill operations, implementing efficient workflow strategies is crucial for enhancing productivity and minimizing downtime. One effective approach is to streamline the production process by organizing workstation layouts for optimal accessibility. This ensures that operators can swiftly transition between tasks, reducing unnecessary movement and allowing for a smoother flow of materials.

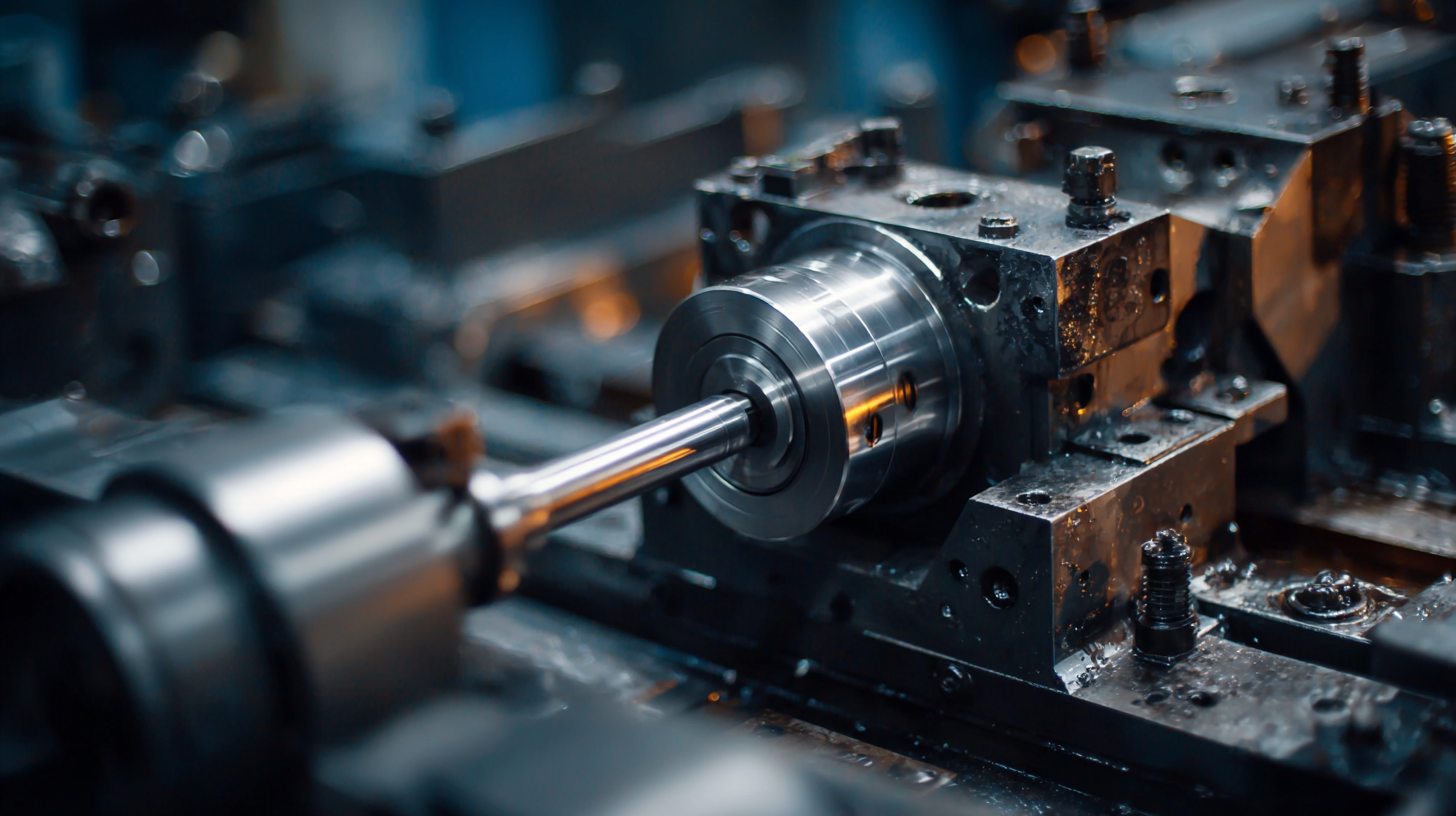

Additionally, incorporating automation technologies into the workflow can significantly boost efficiency. Automated systems can handle repetitive tasks such as cutting and welding, freeing up operators to focus on quality control and other essential responsibilities.

Another vital strategy involves continuous monitoring and data analysis. By utilizing real-time analytics tools, manufacturers can identify bottlenecks and inefficiencies in their production lines. This data-driven approach not only highlights areas for improvement but also facilitates proactive maintenance scheduling, preventing unexpected machinery breakdowns.

Regular training programs for the workforce also play a significant role in maintaining operational efficiency; a well-trained team is more versatile and better equipped to adapt to the dynamism of tube mill operations, ensuring that every step of the process contributes toward optimized production outcomes.

In the ever-evolving landscape of pipe making, utilizing technology and automation is pivotal for optimizing tube mill production. Modern advancements offer innovative solutions that streamline operations, reduce waste, and enhance the quality of the final product. By incorporating smart sensors and IoT devices, manufacturers can monitor real-time data, enabling them to make informed decisions quickly and efficiently.

One essential tip is to implement predictive maintenance using advanced analytics. By analyzing machine data, plant managers can anticipate failures before they occur, minimizing downtime and repair costs. Additionally, automating routine setup processes can significantly reduce lead times and enhance consistency across production runs. This not only saves time but also allows operators to focus on more complex tasks, ultimately boosting productivity.

Moreover, investing in automated quality control systems ensures that products meet industry standards at every stage of production. By leveraging technology for real-time inspections, manufacturers can swiftly identify defects and make necessary adjustments, leading to higher quality outputs. Embracing these technological advancements will not only optimize production processes but also position pipe manufacturers for long-term success in a competitive market.

Training your team effectively is paramount in maximizing efficiency within pipe manufacturing. Start by assessing the current skill levels of your employees to identify gaps in knowledge or areas that require further development. By tailoring training programs to meet the specific needs of your workforce, you can empower them with the technical skills and practical experience necessary to operate tube mills proficiently. Utilizing a mix of hands-on training and theoretical learning will ensure that your team is well-equipped to tackle the inherent challenges in pipe production.

Moreover, fostering a culture of continuous improvement encourages team members to share insights and innovative practices. Regular workshops and collaborative sessions can stimulate problem-solving and creativity, allowing your team to optimize production processes actively. Consider implementing mentorship programs where seasoned employees guide newcomers, creating a cohesive team environment where knowledge is passed on effectively.

By investing in your workforce and creating an atmosphere that values skills enhancement, you not only improve operational efficiency but also boost morale and job satisfaction, leading to lower turnover rates.