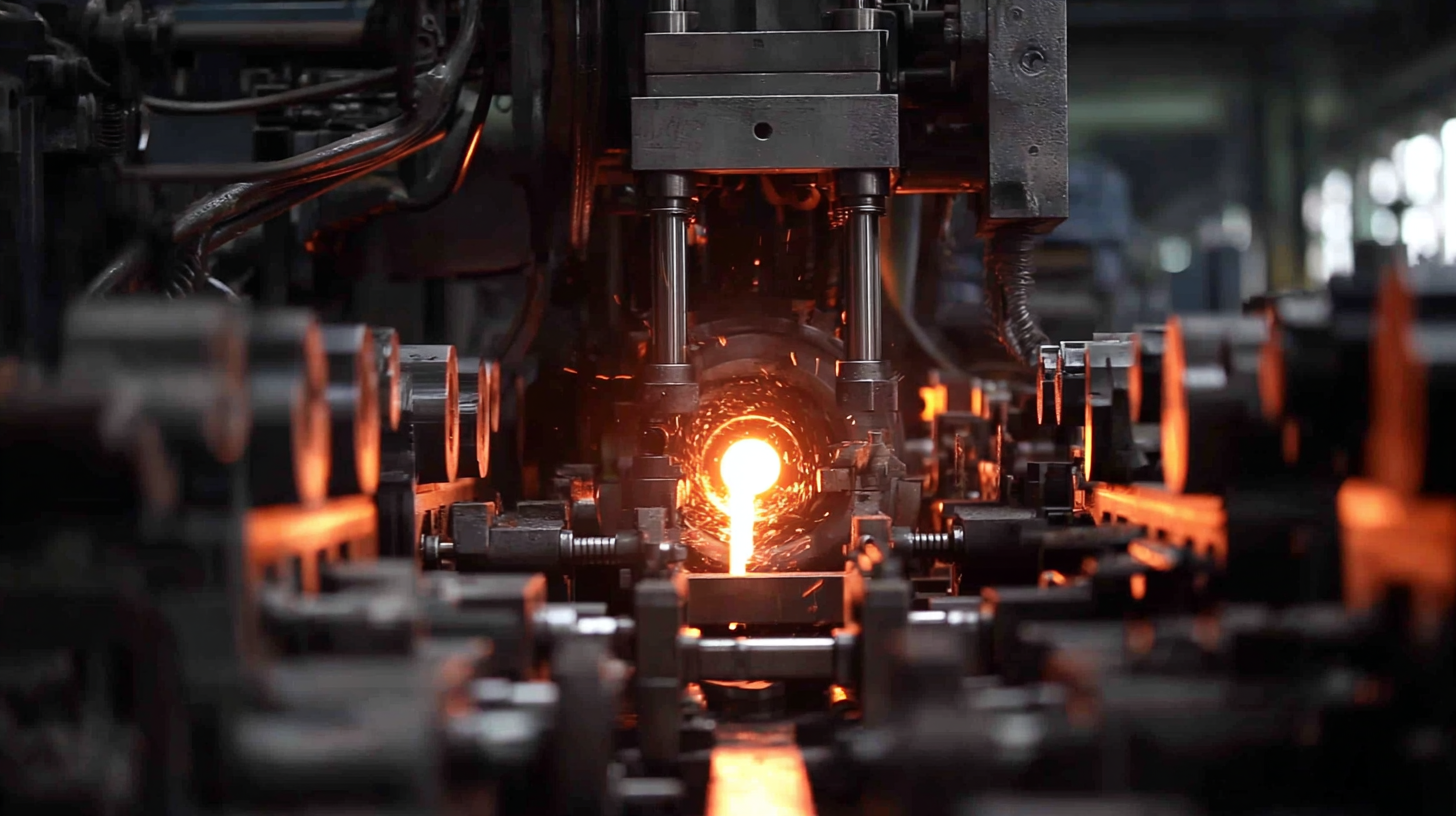

As we look towards 2025, the landscape of manufacturing is set to be revolutionized by cutting-edge trends and innovations, particularly in the field of Tube Mill Pipe Making Machines. According to a recent market report by Research and Markets, the global tube and pipe production machinery market is expected to reach $8.3 billion by 2025, driven by increasing demand from the construction and automotive industries. The advancements in technology are not only enhancing the efficiency of tube mill operations but also significantly reducing waste and energy consumption. By adopting smart manufacturing practices and integrating automation, manufacturers are poised to improve productivity and quality in the pipe-making process.

This blog will explore the benefits of the latest innovations in Tube Mill Pipe Making Machines, highlighting how businesses can leverage these advancements to stay competitive in a rapidly evolving market.

In 2025, the evolution of tube mill pipe making machines will be significantly influenced by

emerging technologies,

enhancing production efficiency and product quality. According to a recent report by

MarketsandMarkets, the global market for tube and pipe manufacturing machinery

is projected to reach $7.2 billion by 2025, driven by innovations

in automation and smart manufacturing solutions. These advancements promise to reduce operational costs while

improving output precision.

One of the key trends is the integration of

AI and machine learning into tube mill processes.

These technologies allow for real-time monitoring and predictive maintenance, minimizing downtime and enhancing

overall efficiency. Additionally, manufacturers are increasingly adopting

advanced materials such as high-strength steels and lightweight

composites, which contribute to the durability and performance of the final products.

One of the key trends is the integration of

AI and machine learning into tube mill processes.

These technologies allow for real-time monitoring and predictive maintenance, minimizing downtime and enhancing

overall efficiency. Additionally, manufacturers are increasingly adopting

advanced materials such as high-strength steels and lightweight

composites, which contribute to the durability and performance of the final products.

Tip 1: Invest in training your workforce

on new technologies to fully harness the benefits of automation and digital tools.

Tip 2: Consider collaborating with tech

companies to tailor cutting-edge solutions specific to your tube manufacturing needs, ensuring you stay ahead

of industry trends.

With these innovations and strategies, businesses can adapt to the dynamic landscape of pipe production and

position themselves as leaders in the market.

The future of tube mill pipe making machines in 2025 is poised for transformative evolution, driven by key innovations in automation and smart manufacturing. With an increasing emphasis on integrating artificial intelligence into manufacturing processes, companies are set to enhance efficiency and reduce production costs. According to recent industry reports, the smart manufacturing market is expected to grow to $400 billion by 2025, highlighting the rapid adoption of smart technologies across various sectors, including pipe manufacturing.

Automation is the cornerstone of these innovations, facilitating the development of high-precision manufacturing techniques. The integration of AI and digital twin technologies allows tube mills to predict maintenance needs, optimize production lines, and ensure quality control. Furthermore, industry trends indicate that companies committed to automation are likely to see a productivity increase of up to 30%. This shift towards intelligent manufacturing not only enhances operational efficiency but also aligns with the global push towards sustainable production practices, paving the way for a greener future in the industry.

As we look ahead, the synergy between smart technologies and traditional manufacturing will redefine qualitative benchmarks within the pipe industry. Key players are increasingly investing in research and development to create automated solutions that leverage real-time data for decision-making, ensuring that tube mill manufacturing is not just reactive but proactively adaptive to market needs.

| Innovation Type | Description | Expected Impact | Implementation Timeline |

|---|---|---|---|

| AI-driven Analytics | Utilization of artificial intelligence for predictive maintenance and production optimization. | Increased operational efficiency and reduced downtime. | 2023-2025 |

| Smart Sensors | Integration of advanced sensors to monitor real-time performance metrics. | Enhanced quality control and reduced scrap rates. | 2024 |

| Robotic Automation | Employment of robots in material handling and assembly processes. | Lower labor costs and increased production speed. | 2023-2025 |

| Digital Twin Technology | Creation of a digital counterpart of the manufacturing process for analysis and simulation. | Improved decision-making and reduced operational risks. | 2025 |

| Integrated Supply Chain Solutions | Platforms that connect production with suppliers and customers for real-time updates. | Streamlined operations and enhanced communication. | 2024-2025 |

As we look ahead to 2025, sustainability in tube mill operations is set to become a critical driver for innovation. Manufacturers are increasingly recognizing the need to minimize their environmental footprint, leading to the development of energy-efficient machines that consume less electricity and reduce waste during production. These advancements not only meet regulatory demands but also resonate with a growing consumer preference for eco-friendly products. The integration of renewable energy sources, such as solar and wind power, into the manufacturing process is expected to gain traction, making operations greener and more self-sufficient.

Moreover, the implementation of circular economy principles is revolutionizing the way tube mill operations function. By focusing on the reuse and recycling of materials, manufacturers can significantly lower their raw material costs while also enhancing their sustainability credentials. Innovations such as advanced materials that are easier to recycle and the development of closed-loop systems will become commonplace, allowing for the reclamation of scrap metal right on the shop floor. This shift not only fosters a more sustainable manufacturing environment but also holds the promise of improving profitability and operational efficiency in the competitive landscape of pipe making.

The landscape of pipe manufacturing is undergoing a revolutionary transformation with the advent of IoT (Internet of Things) and data analytics. In 2025, we can expect that smart tube mill pipe making machines equipped with IoT sensors will be more prevalent, enabling real-time monitoring and optimization of production processes. These machines will gather and transmit data throughout the manufacturing cycle, allowing manufacturers to identify inefficiencies, predict maintenance needs, and improve overall product quality.

Data analytics will play a crucial role in leveraging the vast amounts of information collected by these IoT devices. By applying advanced analytics techniques, manufacturers will be able to gain insights into their operations, from material usage to machine performance. This data-driven approach will facilitate better decision-making and more precise control over the production environment. As a result, companies will not only enhance their efficiency and reduce costs but will also create more sustainable manufacturing practices, meeting the growing demand for environmentally conscious production in the pipe industry.

As the tube mill pipe making industry moves toward 2025, enhancing efficiency and reducing waste has become paramount. Advanced technologies, such as Industry 4.0 and IoT integration, are set to revolutionize production processes. According to a recent report by Grand View Research, the global tube and pipe market is projected to reach $135 billion by 2025, underscoring the importance of innovation in efficiency. Manufacturers are now leveraging data analytics to monitor production in real time, allowing for rapid adjustments that minimize downtime and excess waste.

Moreover, the implementation of automated systems in tube mill operations plays a crucial role in optimizing resource usage. A study from Research and Markets indicates that automation could reduce operational costs by up to 30% while improving product consistency. Techniques such as lean manufacturing, which focuses on streamlining processes and eliminating non-value-added activities, are gaining traction.

By aligning production strategies with these technological advancements and methodologies, companies can not only enhance productivity but also meet the increasing demand for sustainable practices in the industry.