In the ever-evolving landscape of manufacturing and construction, the High Frequency Pipe Welding Machine stands out as a revolutionary tool that enhances efficiency and precision in the welding process. Understanding the intricate mechanics, operational advantages, and essential features of this equipment is crucial for professionals in the industry. From optimizing production rates to ensuring quality welds, the benefits of utilizing high-frequency welding technology are numerous.

In this article, we will delve into the 12 secrets of High Frequency Pipe Welding Machines that every welder, engineer, and contractor should know. These insights will empower you to harness the full potential of this advanced machinery, enabling you to achieve superior results in your projects while minimizing costs and downtime. Whether you're a seasoned expert or a newcomer to the field, this comprehensive guide will equip you with the knowledge needed to excel in your welding endeavors.

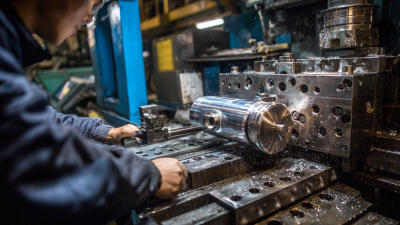

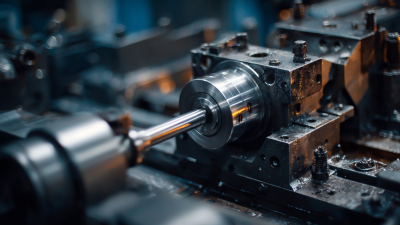

High frequency pipe welding machines are essential tools in the production of ERW (Electric Resistance Welded) steel pipes. At the core of their function is the principle of skin effect—high-frequency currents produce heat along the edges of the formed pipe, allowing for rapid and efficient welding. This process ensures that the steel pipes attain the necessary welding temperature quickly, resulting in strong, durable seams.

Understanding the mechanics behind high frequency welding reveals its advantages. The quick heating minimizes the distortion often seen in other welding techniques, allowing for tighter tolerances and higher quality finishes. Additionally, the integration of high frequency machines in production lines contributes to increased efficiency and reduced operational costs, making them a preferred choice for manufacturers aiming to meet high demand while maintaining quality standards.

High frequency pipe welding machines are equipped with advanced features designed to optimize both welding performance and efficiency. One of the key improvements is the integration of digital controls, which enhance precision by allowing operators to fine-tune welding parameters quickly and accurately. This technology not only reduces the chance of human error but also ensures consistent weld quality across various pipe materials and thicknesses. The ability to store and recall welding programs means that complex projects can be completed more efficiently, minimizing downtime and maximizing productivity.

Another vital feature that enhances welding efficiency is the use of automatic feeding systems. These systems streamline the feeding of pipes into the welding zone, reducing manual intervention and allowing for continuous operation. Additionally, high frequency welding machines often incorporate real-time monitoring systems, which provide immediate feedback on performance metrics. This capability allows operators to make on-the-fly adjustments to maintain optimal conditions, further enhancing the quality of welds while saving time and resources. Together, these features make high frequency pipe welding machines essential tools for modern manufacturing processes.

When it comes to high-frequency pipe welding machines, maintenance is crucial for ensuring longevity and optimal welding quality. One of the fundamental tips is to conduct regular inspections of the machine components. Look for any signs of wear or damage, focusing on parts such as the electrode and cooling system. Replacing worn parts promptly can prevent larger issues and maintain consistent welding performance.

Another essential maintenance tip is to keep the workspace clean and free of contaminants. Dust and debris can affect the calibration and efficiency of the welding machine. Implementing a routine cleaning schedule can help preserve the internal mechanisms and enhance the machine's performance. Additionally, make sure to regularly check the electrical connections and cables for any signs of corrosion or fraying, as these can lead to operational failures.

Lastly, always refer to the manufacturer’s guidelines when performing maintenance. This includes adhering to recommended service intervals and using compatible parts and consumables. Following these practices will not only extend the life of your high-frequency pipe welding machine but also ensure that your welding operations remain of the highest quality.

| Secret Number | Maintenance Tip | Benefits | Frequency of Maintenance |

|---|---|---|---|

| 1 | Regular Cleaning of Components | Prevents buildup and extends equipment life | Weekly |

| 2 | Check Electrical Connections | Ensures steady power supply for consistent performance | Monthly |

| 3 | Inspect Cooling System | Prevents overheating and damage to components | Bi-Monthly |

| 4 | Check Welding Parameters | Ensures optimal settings for quality welds | Every Weld Session |

| 5 | Replace Worn Out Electrodes | Maintains efficiency and weld integrity | Per Project |

| 6 | Monitor Gas Flow Rates | Ensures proper shielding during welding | Before Each Session |

| 7 | Calibrate Machine Regularly | Enhances precision and accuracy in welding | Quarterly |

| 8 | Inspect For Leaks in Cooling Lines | Prevents coolant loss and overheating | Monthly |

| 9 | Update Software & Controls | Ensures access to the latest features and fixes | As Needed |

| 10 | Assess and Adjust Grounding System | Reduces risks of electrical failure | Semi-Annual |

| 11 | Keep a Log of Maintenance Activities | Helps track performance and identify issues | Ongoing |

| 12 | Train Operators Regularly | Ensures safe and effective use of equipment | Annually |

High frequency pipe welding is becoming increasingly essential in various industries, particularly in sectors like mining where durability and efficiency are paramount. However, several challenges often arise during the welding process. One common issue is the difficulty in maintaining consistent weld quality due to fluctuations in frequency and power supply. Research indicates that improper frequency settings can lead to weld defects, resulting in up to a 30% decrease in strength in welded joints. Therefore, utilizing high-frequency machines designed to maintain optimal settings is crucial to enhancing productivity and ensuring weld integrity.

Another significant challenge in high frequency pipe welding is managing the thermal distortion that can occur during the welding process. Thermal expansion can affect the alignment of pipes, leading to misalignment and potential failure points. According to industry data, effective management of thermal distortion can reduce the occurrence of defects by as much as 50%. Techniques such as pre-heating the material or employing advanced cooling methods have proven effective. With advancements in equipment like the all-in-one solutions tailored for rugged environments, the industry can tackle these challenges head-on, ensuring consistent quality and efficiency in high frequency pipe welding operations.

When operating a high-frequency pipe welding machine, prioritizing safety is paramount. The first line of defense is to ensure that all operators are adequately trained and familiar with the specific machine being used.

Comprehensive training includes understanding the machine's controls, settings, and emergency protocols. This knowledge is crucial for mitigating risks and ensuring a smooth workflow.

Additionally, proper personal protective equipment (PPE) such as gloves, goggles, and welding masks should always be worn to protect against sparks, radiation, and high temperatures.

When operating a high-frequency pipe welding machine, prioritizing safety is paramount. The first line of defense is to ensure that all operators are adequately trained and familiar with the specific machine being used.

Comprehensive training includes understanding the machine's controls, settings, and emergency protocols. This knowledge is crucial for mitigating risks and ensuring a smooth workflow.

Additionally, proper personal protective equipment (PPE) such as gloves, goggles, and welding masks should always be worn to protect against sparks, radiation, and high temperatures.

Another critical safety measure involves maintaining a clutter-free workspace. Ensure that the area around the welding machine is clear of flammable materials and that all safety equipment, such as fire extinguishers, is easily accessible. Regular inspections of the welding machine's cables and connections are also vital, as frayed or damaged equipment can pose serious hazards. Furthermore, operators should never work alone; having a buddy system in place can provide immediate assistance in case of an emergency. By adhering to these safety measures, operators can significantly minimize risks and enhance the overall safety of welding operations.