The manufacturing landscape is undergoing a transformative evolution, largely driven by advancements in technology and the increasing demand for efficiency. Among these innovations, the High Frequency Tube Mill Making Machine stands out as a pivotal player in modern manufacturing processes. According to a recent industry report by MarketsandMarkets, the global market for tube and pipe manufacturing machinery is expected to reach $9.03 billion by 2025, growing at a CAGR of 4.3%. This growth is being propelled by the rising need for lightweight and high-strength materials in industries such as automotive and construction. The High Frequency Tube Mill Making Machine, with its ability to produce high-precision tubes at unprecedented speeds, is revolutionizing production lines and significantly optimizing resource utilization. As manufacturers strive to enhance output while reducing costs, the incorporation of these machines is becoming not just beneficial, but essential for maintaining competitive advantage in today’s fast-paced market.

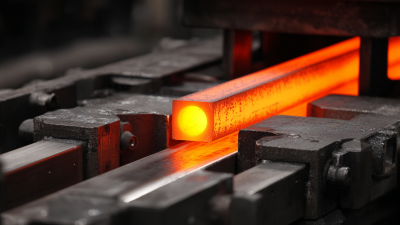

The evolution of high frequency tube mill technology marks a significant turning point in the manufacturing industries. Over the past century, the transition from traditional methods to high frequency welding has allowed for the production of seamless steel pipes and tubes with enhanced precision and efficiency. Pioneered in the 20th century, high frequency tube mills utilize electromagnetic energy to weld edges of metal strips, minimizing material waste and optimizing production speeds. This innovation not only redefined manufacturing processes but also increased the quality and durability of the final products, which are essential in various applications, from automotive to construction.

Tips: When considering the implementation of high frequency tube mill technology, manufacturers should focus on investing in modern equipment that integrates in-process monitoring strategies. This can significantly enhance the quality control of metal forming processes. Additionally, understanding the microstructural changes in materials, as highlighted in studies involving cladding tubes, can further improve product outcomes. Embracing these advancements will contribute to a more efficient and sustainable manufacturing future.

High Frequency Tube Mills (HFTMs) are transforming the landscape of modern manufacturing by offering several key advantages over traditional methods. Unlike conventional tube manufacturing processes that rely heavily on welding and machining, HFTMs utilize high-frequency electromagnetic induction to produce tubes with higher precision and speed. According to a report by MarketsandMarkets, the global market for high frequency welded tubes is expected to reach $4.82 billion by 2025, reflecting a significant shift toward these efficient technologies.

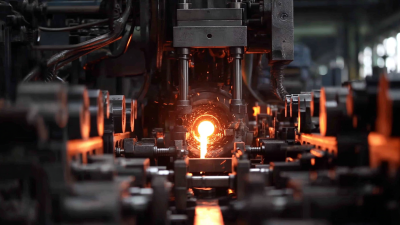

One of the standout benefits of HFTMs is their operational efficiency. They can produce up to 200 meters of tubing per minute, significantly faster than traditional tube mills, which have slower production rates that average around 30 meters per minute. This increase in speed correlates directly with enhanced productivity and lower production costs. Additionally, HFTMs produce less material waste, as their precise control reduces errors during the manufacturing process, leading to an estimated waste reduction of up to 25%, as highlighted in a recent study by the Tube and Pipe Association.

Tips: For manufacturers looking to upgrade their operations, investing in HFTMs could yield substantial returns. Consider conducting a thorough cost-benefit analysis to measure potential savings from reduced labor and minimized waste. Furthermore, keeping abreast of technology updates in HFTMs can help you stay competitive in a rapidly evolving market.

High frequency tube mills have emerged as game-changers in modern manufacturing, significantly impacting production efficiency and cost reduction. According to a recent report by Allied Market Research, the global tube and pipe manufacturing equipment market is projected to reach $7.2 billion by 2027, with high frequency tube mills accounting for a substantial share. These machines enable faster production rates, often exceeding 100 meters per minute, compared to traditional methods that may only reach half of that speed. This increase allows manufacturers to meet growing market demands more efficiently.

Additionally, high frequency tube mills contribute to cost reductions by minimizing material waste and energy consumption. The process of welding tubes using high-frequency induction not only ensures a stronger bond but also reduces the energy used in the welding process by up to 30%, according to a study by Research and Markets. Moreover, the ability to produce various tube sizes and types without extensive reconfiguration lowers operational downtimes, allowing for a more streamlined manufacturing process. As a result, companies leveraging high frequency tube mills can expect significant improvements in both their production output and overall profitability.

The adoption of High Frequency Tube Mill making machines has seen remarkable growth in recent years, reflecting the increasing demand for efficient manufacturing solutions. According to industry statistics, the market for these machines has expanded steadily, with a compound annual growth rate (CAGR) of over 8% projected through the next five years. This surge can be attributed to the rising need for high-quality, precision-engineered tubes in key sectors such as automotive, construction, and energy. Manufacturers are investing in high frequency technology to enhance their production capabilities, reduce lead times, and minimize waste.

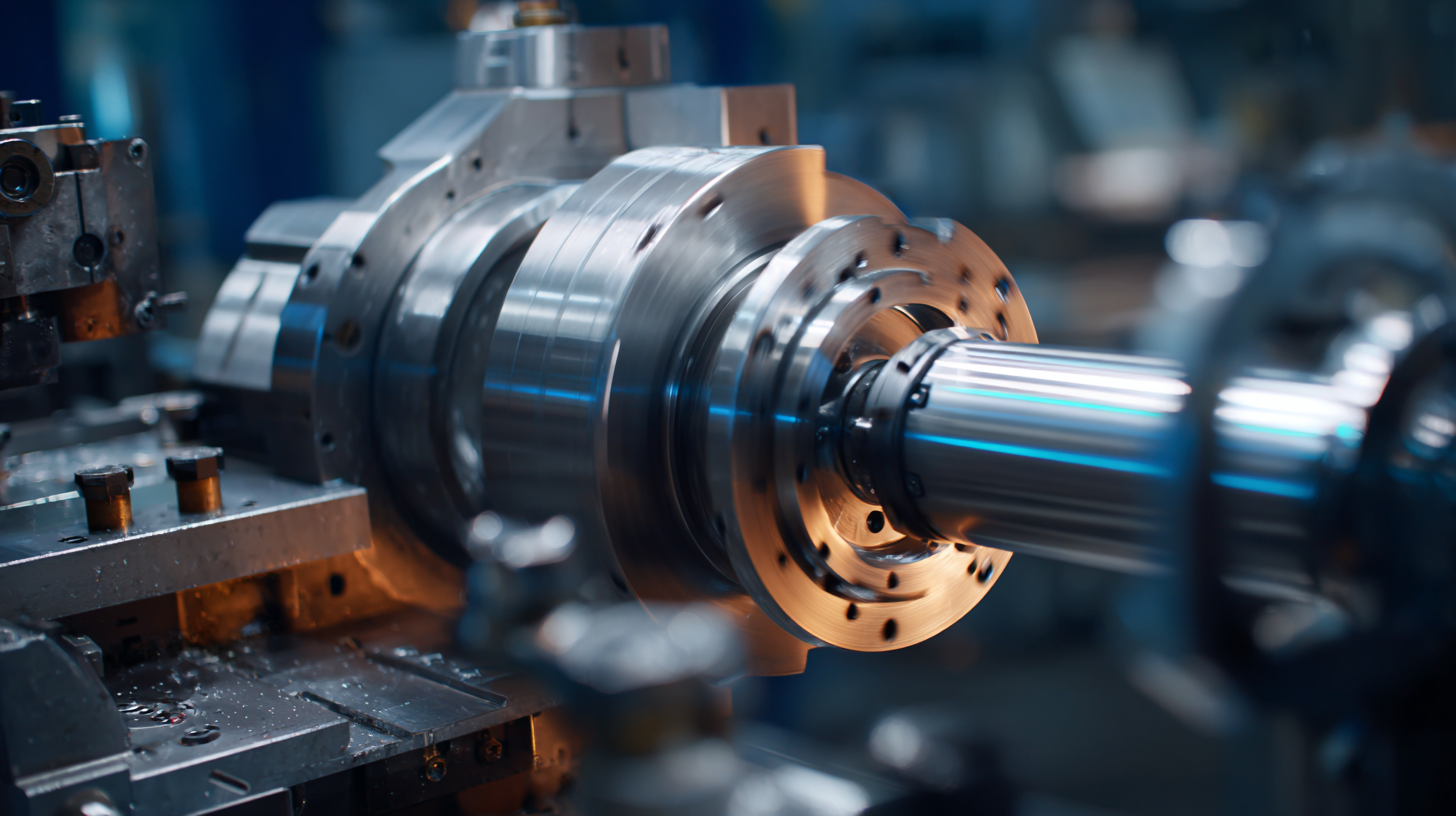

Moreover, the shift toward automation and smart manufacturing continues to drive the demand for High Frequency Tube Mills. Innovations in machine controls and processes make these mills more versatile and reliable, allowing producers to quickly adapt to changing market requirements. The integration of advanced technologies, like Industry 4.0 solutions, further supports efficiency and productivity, solidifying the high frequency tube mill's position as an essential tool in modern manufacturing. As industries recognize the benefits of adopting this technology, it is likely we will see an accelerated trend in their implementation, reshaping production landscapes across various sectors.

The landscape of tube mill machines is evolving rapidly, driven by technological advancements and increasing demand for efficiency in manufacturing. According to a recent report by Markets and Markets, the global tube mill market is projected to reach $2.3 billion by 2026, growing at a compound annual growth rate (CAGR) of 4.5%. This growth is largely attributed to innovations in high-frequency tube mill making machines, which enhance production capabilities while minimizing waste.

One key trend shaping the development of these machines is the integration of automation and Industry 4.0 technologies. Manufacturers are increasingly adopting smart tubes and digital monitoring systems that allow for real-time data analysis and process optimization. According to a study by Grand View Research, the adoption of automation in manufacturing processes can increase operational efficiency by up to 30%. Furthermore, advancements in materials technology are enabling the creation of thinner and lighter tubes, which not only reduce raw material usage but also improve the sustainability profile of production processes. As these trends continue to unfold, the tube mill industry is set to become a cornerstone of modern manufacturing efficiency.