In recent years, the demand for High Quality Steel Pipe Machines Tube Mill has surged, driven by the rapid industrial growth and infrastructure development worldwide. According to a report by the World Steel Association, global steel production reached 1.9 billion metric tons in 2021, with a projected annual growth rate of 3% through 2025. This expansion presents significant opportunities for manufacturers to enhance efficiency and output in tube milling operations.

By leveraging advanced technologies and optimizing production processes, companies can achieve higher quality standards and reduce operating costs. As we explore the evolving landscape of steel pipe manufacturing, it becomes increasingly vital to understand the best practices and innovative techniques that can maximize the efficiency of High Quality Steel Pipe Machines Tube Mill, ensuring competitiveness in an ever-expanding market.

By leveraging advanced technologies and optimizing production processes, companies can achieve higher quality standards and reduce operating costs. As we explore the evolving landscape of steel pipe manufacturing, it becomes increasingly vital to understand the best practices and innovative techniques that can maximize the efficiency of High Quality Steel Pipe Machines Tube Mill, ensuring competitiveness in an ever-expanding market.

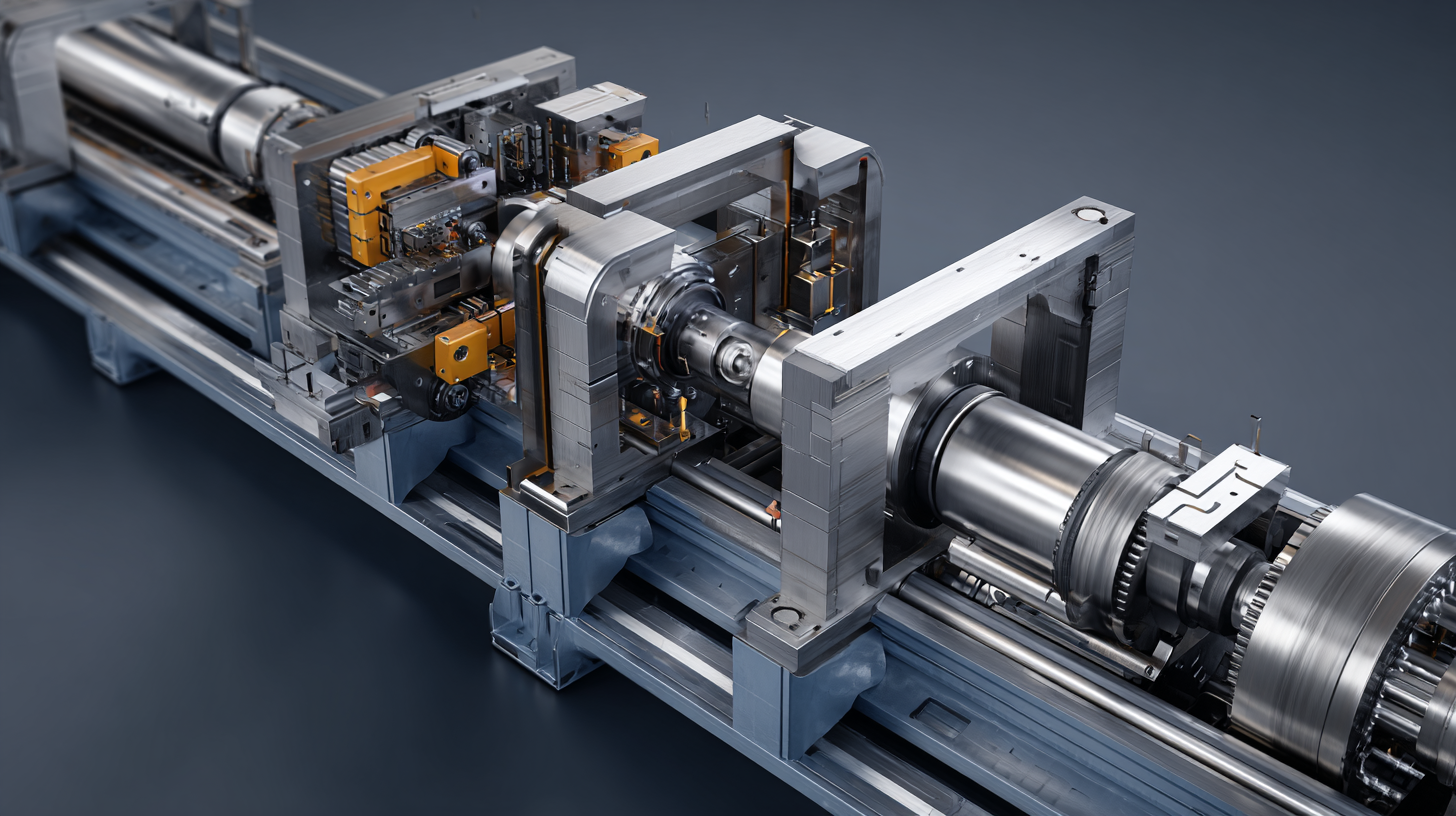

Advancements in tube mill technology are transforming the production landscape for high-quality steel pipes, particularly in the growing market for stainless steel seamless pipes, which is projected to reach USD 5.15 billion by 2030. With innovations such as high frequency straight seam welding, manufacturers can now produce ERW steel pipes with remarkable efficiency. This process leverages the skin and proximity effects to create strong, seamless pipes essential for various industrial applications.

To maximize efficiency in tube mill operations, manufacturers should focus on modernizing equipment and integrating advanced monitoring systems. Implementing fiber laser technology not only enhances cutting capabilities but is also making significant strides in welding applications, resulting in reduced cycle times and improved weld quality.

**Tips for Efficiency:**

1. Invest in high-quality machinery that can adapt to different production demands.

2. Regularly monitor product quality throughout the welding and forming processes to identify and mitigate issues early.

3. Stay informed about the latest technological advancements that can enhance productivity and product quality.

The global market for stainless steel seamless pipes is set to reach USD 5.15 billion by 2030, reflecting the increasing demand for high-quality steel products across various industries. This surge is largely attributed to the expanding applications in construction, automotive, and infrastructure development, which are driving the need for durable and corrosion-resistant tubing solutions. Businesses looking to capitalize on this trend must focus on maximizing production efficiency and adopting advanced manufacturing technologies that enhance product quality and reduce waste.

In the competitive landscape of the steel pipes market, recent IPOs of steel tube manufacturers indicate a strong investor interest, showcasing confidence in sector growth. For instance, certain companies have debuted with significant premiums, illustrating robust market sentiment. Moreover, the seamless steel tubes market, valued at $45.5 billion in 2022, is anticipated to grow to $84.9 billion by 2032, highlighting the broader trend of rising demand for high-performance steel solutions.

As manufacturers innovate and optimize their processes, staying informed about market dynamics and consumer preferences will be essential for both established and emerging players in the steel industry.

In the realm of steel pipe manufacturing, efficiency metrics play a crucial role in determining the output and overall cost-effectiveness of operations. By closely evaluating production processes, manufacturers can identify bottlenecks that hinder productivity and implement strategic improvements. Key performance indicators (KPIs) such as cycle time, scrap rate, and equipment utilization provide insights into the operational health of tube mills. Regular monitoring of these metrics enables manufacturers to optimize their workflows, ensuring that machinery operates at peak performance.

Furthermore, leveraging advanced technologies, such as automation and data analytics, can significantly enhance the efficiency of steel pipe manufacturing systems. For instance, predictive maintenance tools can reduce downtime by anticipating mechanical failures before they occur. Additionally, optimizing raw material usage and streamlining logistics can lower production costs while maintaining high-quality standards. By focusing on these areas and utilizing data-driven insights, manufacturers can maximize efficiency, reduce waste, and ultimately improve their competitive edge in the steel pipe industry.

| Application Area | Machine Type | Efficiency Metric | Output (Tons/Day) | Cost Optimization ($/Ton) |

|---|---|---|---|---|

| Oil and Gas Pipeline | High-Speed Tube Mill | 90% Material Utilization | 500 | 1,200 |

| Construction Industry | Seamless Pipe Machine | 85% Energy Efficiency | 300 | 1,500 |

| Automotive Sector | Welded Pipe Mill | 95% Production Yield | 450 | 1,100 |

| Shipbuilding | Straight Seam Pipe Machine | 88% Efficiency Rate | 600 | 1,300 |

| Energy Sector | Spiral Pipe Mill | 92% Waste Reduction | 350 | 1,400 |

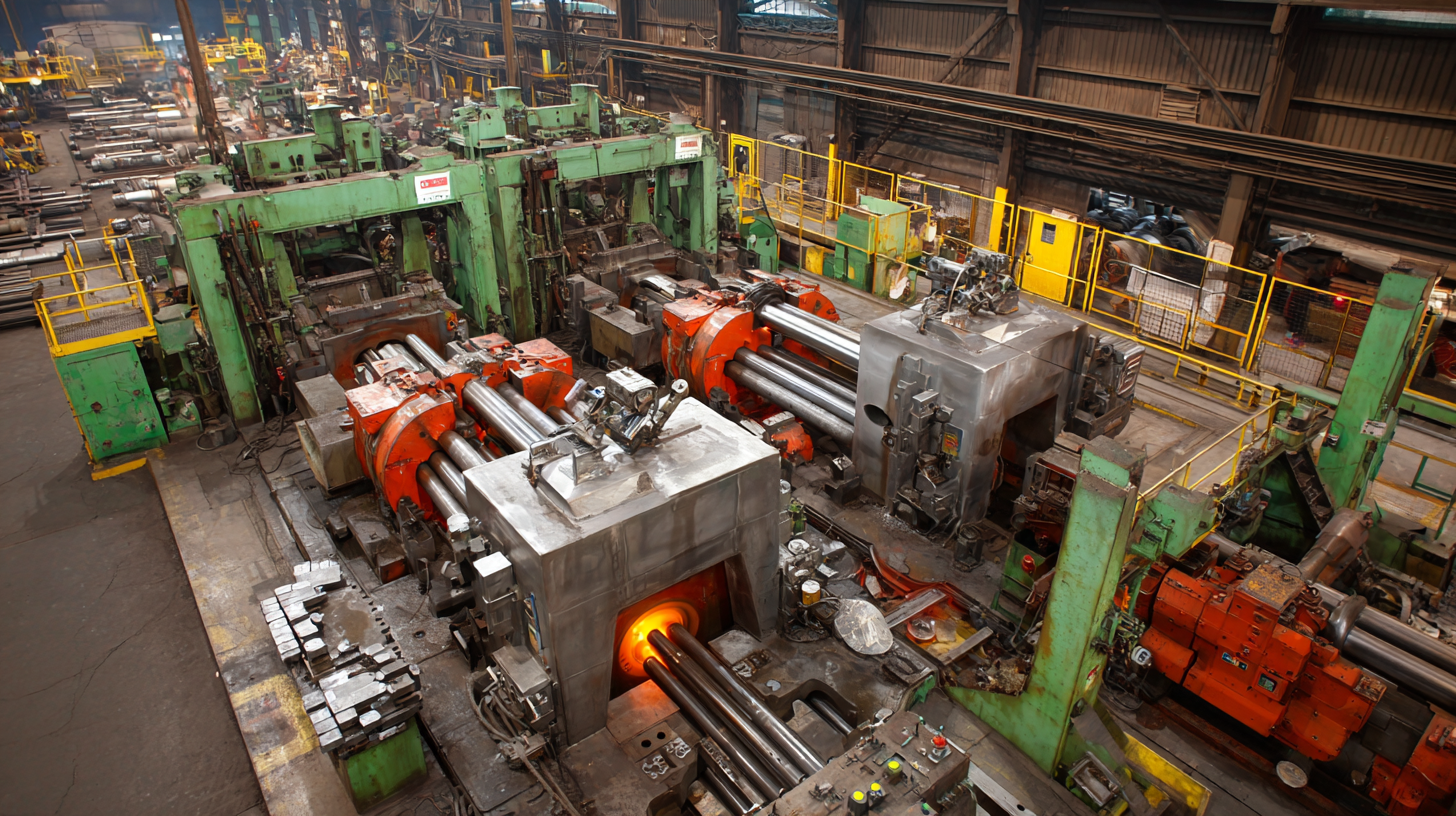

The global steel pipe industry has witnessed remarkable advancements, particularly in the application of high-quality steel pipe machines. Various case studies highlight how these machines have been instrumental across different sectors, from automotive to construction. For instance, manufacturers producing steel wheels for the auto aftermarket have experienced a significant boost in efficiency through the use of state-of-the-art tube mills. These machines not only streamline production processes but also enhance product quality, helping businesses maintain competitive advantages in saturated markets.

Additionally, in the realm of architectural products, the application of advanced steel pipe machines has led to the creation of iconic structures while ensuring durability and sustainability. The ERW (Electric Resistance Welded) steel pipes, produced with cutting-edge technology, are increasingly favored for their reliability and cost-effectiveness. Reports indicate a promising growth trajectory for the pipe fittings market, projected to expand significantly over the next decade. By embracing these high-quality steel pipe machines, industries can optimize their manufacturing processes, lower operational costs, and meet growing global demands effectively.

As the steel industry continues to evolve, the future of tube mill operations lies in embracing innovations that enhance sustainability and efficiency. Advanced technologies such as automated control systems and real-time monitoring play a critical role in optimizing production processes. By integrating these technologies, manufacturers can reduce waste and energy consumption while ensuring high-quality output.

**Tips for Maximizing Efficiency:** Implementing predictive maintenance systems can significantly minimize downtime. Regularly scheduled maintenance helps identify potential issues before they disrupt production, contributing to a smoother workflow. Additionally, consider using high-quality materials and components in machinery to improve durability and reduce the frequency of replacements.

Sustainability is increasingly becoming a key focus in steel pipe production. Incorporating recycled materials not only reduces raw material costs but also minimizes environmental impact. Furthermore, adopting energy-efficient practices, such as utilizing renewable energy sources, can substantially decrease a company's carbon footprint. By staying ahead of these emerging trends, businesses can secure a competitive edge in the industry while promoting a greener future.

This chart illustrates the efficiency metrics of different types of steel pipe machines based on production output and energy consumption for the year 2023.