The evolution of manufacturing technology has significantly influenced various industries, particularly in the production of high-quality metal tubes. At the forefront of this sector is the High Frequency Tube Mill Making Machine, which has demonstrated remarkable advancements in efficiency and output. According to a report by MarketsandMarkets, the global tube and pipe market is projected to reach USD 150 billion by 2025, bolstered by the increasing demand for precision-engineered products across industries including construction, automotive, and oil and gas.

The 138th China Import and Export Fair in 2025 will showcase these cutting-edge machines, offering insights into how they enhance productivity and reduce operational costs. As manufacturers continuously seek to optimize their production processes, the development and adoption of High Frequency Tube Mill Making Machines are expected to play a pivotal role in meeting the dynamic needs of the market, thus fostering innovation and growth in the global metalworking industry.

The landscape of tube mill manufacturing is witnessing significant innovations and advancements, particularly highlighted at the 2025 China Import and Export Fair.

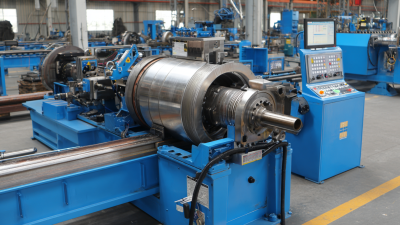

High Frequency Tube Mill Making Machines, known for their enhanced productivity and precision, are at the forefront of these developments. According to a recent industry report by Market Research Future, the global demand for high-frequency welded tubes is projected to grow at a CAGR of 8.5% from 2023 to 2030, driven largely by increasing applications in automotive and construction industries.

High Frequency Tube Mill Making Machines, known for their enhanced productivity and precision, are at the forefront of these developments. According to a recent industry report by Market Research Future, the global demand for high-frequency welded tubes is projected to grow at a CAGR of 8.5% from 2023 to 2030, driven largely by increasing applications in automotive and construction industries.

One of the noteworthy advancements in high frequency tube mill technology is the integration of Industry 4.0 principles, facilitating real-time data analytics and automation. This transition not only streamlines production processes but also significantly reduces waste and downtimes. Furthermore, companies are increasingly adopting energy-efficient systems, as noted by a report from ResearchAndMarkets, which indicates that energy-efficient tube mill machines can lower operational costs by up to 30%. The growing emphasis on sustainability and efficiency is reshaping competitive dynamics in the industry, making high frequency tube mills more appealing to manufacturers aiming to enhance their operational capabilities.

As we approach the 2025 China Import and Export Fair, the demand for tube mill technology is set to rise significantly. According to industry projections, the global market for tube mills is expected to grow at a CAGR of approximately 7% from 2023 to 2028. The surge in demand can be attributed to increasing applications in the automotive, construction, and energy sectors. Notably, the recent advancements in gas turbine technology, particularly the exporting initiatives observed in countries like Iran, highlight the growing importance of efficient and reliable manufacturing processes, such as those provided by high-frequency tube mill making machines.

Moreover, the tube mill market is also experiencing an expansion in downstream applications. Reports indicate that the use of tube mills is becoming critical in the production of high-performance components, especially in the aerospace and oil and gas industries. As technology continues to evolve, manufacturers are focusing on enhancing production efficiency and product quality, thus driving up the demand for advanced tube mill machinery. In this dynamic landscape, adapting to technological advancements and understanding market needs will be crucial for industry players looking to thrive by the time the fair concludes in 2025.

The tube mill industry is witnessing significant transformations as major players leverage advanced technologies to enhance production efficiency and product quality. As the demand for welded and high-pressure seamless pipes surges, driven by robust applications in construction and infrastructure projects, key manufacturers are strategically positioning themselves to capture emerging opportunities in the market. Competitive dynamics are shaped by the need for innovation and the establishment of effective supply chains, particularly in regions like MENA, where external factors such as tariffs pose challenges to operational costs.

Furthermore, the 2025 China Import and Export Fair serves as a pivotal platform for industry stakeholders to showcase their capabilities and explore collaborations. It highlights the ongoing trends and growth drivers within the sector, including the shift towards high-frequency tube mill making machines, which offer enhanced productivity and versatility. As companies continuously adapt to market shifts, the focus remains on capitalizing on emerging technologies and meeting the increasing demands of customers worldwide, ensuring they maintain a competitive edge in the evolving landscape of tube manufacturing.

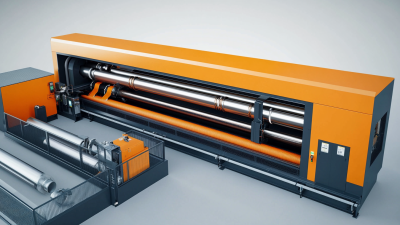

The 2025 China Import and Export Fair is set to showcase significant advancements in the tube mill manufacturing sector, particularly emphasizing sustainability and eco-friendly practices. As industries increasingly recognize the impact of their production processes on the environment, manufacturers are innovating to incorporate green technologies. This includes utilizing energy-efficient systems that reduce carbon footprints and adopting biodegradable materials in their manufacturing processes.

Furthermore, the development of high-frequency tube mill making machines represents a notable shift towards sustainable practices. These machines not only enhance production efficiency but also minimize waste through precise engineering and reduced energy consumption. Manufacturers are investing in research and development to integrate renewable energy sources into their operations, which further supports global sustainability efforts. By prioritizing ecological solutions, the tube mill industry is committed to fostering a cleaner, more sustainable future while meeting the demands of a rapidly evolving market.

The 2025 China Import and Export Fair is set to showcase transformative trends in the tube mill sector, reflecting the industry's ongoing evolution. As technological advancements accelerate, high frequency tube mill making machines are becoming increasingly sophisticated. Notably, innovations such as automation, energy efficiency, and smart technology integration are reshaping production processes. Manufacturers are now leveraging artificial intelligence and machine learning to enhance operational efficiency and reduce downtime, which significantly impacts overall productivity.

Furthermore, sustainability is emerging as a critical focus for the tube mill industry. With a growing emphasis on environmental responsibility, companies are adopting greener practices and materials in their production lines. This shift not only meets regulatory demands but also aligns with consumer preferences for eco-friendly products. The fair will highlight how these trends are driving competitiveness and fostering collaboration among industry stakeholders, setting a benchmark for future developments in the tube mill sector. As stakeholders gather to share insights, the 2025 fair is poised to outline a roadmap for the industry's future, ensuring that it adapts to both market demands and technological advancements.

| Trend Dimension | Current Situation | Future Outlook | Impact on Industry |

|---|---|---|---|

| Automation | Increasing integration of automation technologies. | Expect significant growth in automation solutions. | Improved efficiency and productivity. |

| Sustainability | Growing focus on eco-friendly practices. | Increased demand for sustainable manufacturing processes. | Enhanced brand value and customer loyalty. |

| Material Innovation | Use of advanced materials in tube manufacturing. | Emerging use of lightweight and stronger materials. | Improved product performance and competitiveness. |

| Digitalization | Incorporation of IoT and data analytics. | Widespread adoption of smart technologies. | Better decision making and operational efficiency. |

| Market Expansion | Steady growth in emerging markets. | Potential for rapid market growth by 2025. | Opportunities for new business ventures. |