In recent years, advancements in Carbon Steel Tube Mill Pipe Making Machine technology have significantly transformed the efficiency of pipe production across various industries. According to a report by MarketsandMarkets, the global market for steel pipes is projected to reach $105.82 billion by 2027, with a compound annual growth rate (CAGR) of 6.4% from 2022 to 2027. This growth is largely driven by increasing demand in construction, automotive, and oil and gas sectors, where reliable and durable piping solutions are critical.

Innovations in manufacturing processes, such as enhanced automation capabilities and precision engineering, have enabled manufacturers to produce higher-quality pipes with reduced energy consumption and waste. As a result, understanding the latest developments in Carbon Steel Tube Mill technology is essential for industry stakeholders aiming to enhance their production efficiency and compete effectively in a rapidly evolving market landscape.

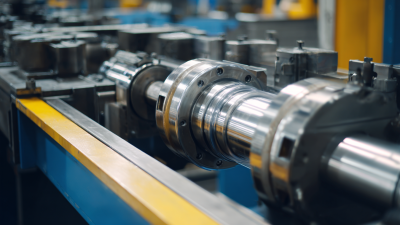

The innovative machinery designs in carbon steel tube mills are leading a significant transformation in the efficiency of pipe production. These advancements are not only enhancing throughput but also improving the precision and quality of the produced pipes. Modern tube milling technologies integrate automation and advanced materials, allowing manufacturers to reduce waste and optimize resource utilization. As a result, companies are now able to achieve higher production rates while maintaining stringent quality standards, a crucial requirement in today’s competitive market.

In parallel to these innovations in the carbon steel sector, we are witnessing revolutionary developments across various engineering fields, such as subsea decommissioning. Techniques and machinery designed for these processes reflect a broader trend towards maximizing operational efficiency and safety, much like the improvements seen in tube mill technology. This synergy of advanced engineering solutions illustrates how industries are continuously evolving, seeking innovative approaches to enhance existing processes and confront the challenges of modern production demands.

The advancements in automation technology have significantly transformed the carbon steel tube mill industry, especially in pipe production efficiency. With the integration of smart machinery and IoT systems, manufacturers can now monitor and control production processes in real-time, reducing human error and enhancing precision. Automated systems facilitate faster setup times and seamless transitions between different production runs, ensuring that manufacturers respond swiftly to market demands without sacrificing quality.

Tips for improving automation in your production line include investing in high-quality sensors that provide accurate data on material conditions and machine performance. Regularly update your software systems to incorporate the latest features that enhance operational efficiency and safety protocols. Collaborating with technology providers who specialize in automation solutions can also lead to tailored strategies that meet your specific production challenges.

Moreover, predictive maintenance powered by advanced algorithms helps in identifying potential machine failures before they occur, minimizing downtime. Implementing a lean manufacturing approach alongside automation can streamline processes and reduce waste, leading to a more sustainable production environment. By prioritizing automation in carbon steel tube mills, companies can achieve remarkable increases in productivity, ultimately positioning themselves competitively in the market.

The push for energy-saving technologies in carbon steel manufacturing is critical for achieving sustainability in the industry. With the steel sector responsible for approximately 7-9% of global carbon emissions, adopting green steel practices has become paramount. Recent developments indicate that leading companies are focusing on innovative production methods that harness renewable energy sources, significantly reducing their environmental impact. For instance, the use of organic solid waste as both a fuel and a reducing agent in steelmaking exemplifies innovative approaches aimed at minimizing carbon footprints.

The push for energy-saving technologies in carbon steel manufacturing is critical for achieving sustainability in the industry. With the steel sector responsible for approximately 7-9% of global carbon emissions, adopting green steel practices has become paramount. Recent developments indicate that leading companies are focusing on innovative production methods that harness renewable energy sources, significantly reducing their environmental impact. For instance, the use of organic solid waste as both a fuel and a reducing agent in steelmaking exemplifies innovative approaches aimed at minimizing carbon footprints.

Tips: Investing in green technologies can yield substantial financial benefits in the long term. Companies engaged in the transition to low-carbon steel production often experience enhanced operational efficiencies and reduced energy costs. Furthermore, partnerships across the supply chain can amplify the impact of sustainability initiatives.

The implementation of smart production technologies, including carbon accounting and life cycle assessments, offers a feasible pathway for the steel industry to align with global emissions targets. As seen in recent studies, companies that undertake these measures not only elevate their market competitiveness but also contribute to the overarching goal of combating climate change. Transitioning to a portfolio of cleaner technologies is no longer optional; it is a strategic necessity for sustainable industrial growth.

The integration of smart monitoring systems in industrial automation represents a significant leap forward in production quality control. These systems enable real-time data analytics, allowing manufacturers to monitor their processes continuously and make timely adjustments. By leveraging advanced technologies, manufacturers can enhance the efficiency of carbon steel tube mills, ensuring that pipe production meets stringent quality standards while reducing waste and downtime.

As the manufacturing landscape evolves, the demand for intelligent solutions grows. The production monitoring market is projected to expand, driven by the need for enhanced visibility and improved operational performance. Companies are increasingly investing in sophisticated tools that facilitate seamless data flows and support predictive maintenance. This shift not only boosts production efficiency but also refines the overall quality control processes, enabling manufacturers to deliver consistent and reliable products to the market.

| Parameter | Description | Value |

|---|---|---|

| Tube Diameter | Range of diameters produced | 20 mm - 200 mm |

| Wall Thickness | Thickness range for pipes | 1 mm - 10 mm |

| Production Speed | Speed of production lines | 60 m/min |

| Smart Monitoring | Real-time quality control system | Yes |

| Yield Strength | Minimum yield strength of steel | 350 MPa |

| Waste Reduction | Percentage waste reduction achieved | 20% |

| Production Efficiency | Overall production efficiency | 90% |

| Energy Consumption | Energy used per ton of pipes | 500 kWh |

The future of carbon steel tube mill technology is poised for significant advancements aimed at enhancing pipe production efficiency. As manufacturers strive for heightened competitiveness and sustainability, innovations such as smart automation and data analytics are expected to play crucial roles. These technologies will not only optimize production processes but also provide real-time monitoring and predictive maintenance, reducing downtime and increasing throughput.

Moreover, the integration of advanced materials and precision engineering will likely lead to improvements in product quality and performance. For example, the usage of higher-grade steel and improved welding techniques can enhance durability and reduce weight in pipe applications. It is also anticipated that the continued push for environmentally friendly practices will drive the development of energy-efficient machinery and processes within the sector, aligning with global sustainability goals. As these trends unfold, the carbon steel tube mill industry will witness a transformation that caters to evolving market demands while prioritizing efficiency and environmental responsibility.