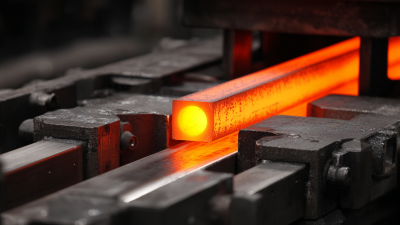

In the competitive landscape of modern manufacturing, investing in Custom Tube Mill Pipe Making Machinery is a pivotal strategy for businesses aiming to enhance their operational efficiency and product quality. As John Smith, a leading expert in manufacturing technologies, aptly stated, “The right machinery not only improves production rates but also significantly reduces waste, leading to greater profitability.” This perspective highlights the critical role that advanced machinery plays in streamlining processes and ensuring precision.

Custom Tube Mill Pipe Making Machinery offers tailored solutions that meet the specific needs of various industries, from construction to automotive. By integrating advanced technology, businesses can achieve higher accuracy in their pipe production, which can result in better product performance and reduced operational costs. Furthermore, with the capability of producing custom configurations and sizes, companies are empowered to cater to diverse customer demands swiftly and effectively.

As companies continue to adapt to ever-evolving market dynamics, the significance of investing in Custom Tube Mill Pipe Making Machinery cannot be overstated. It not only represents an investment in state-of-the-art technology but also in the future of a business poised for growth and efficiency. Embracing this machinery could very well be the turning point that propels a company ahead of its competitors in a crowded marketplace.

Custom tube mill pipe making machinery plays a pivotal role in the manufacturing sector, especially for businesses engaged in metal fabrication. As industries demand higher precision and efficiency, investing in customized machinery can significantly influence production capabilities. According to a report by Industry Research, the global tube and pipe market is projected to reach $150 billion by 2025, with growing applications in sectors such as construction, automotive, and HVAC systems. Custom tube mills offer flexibility and adaptability to handle a variety of pipe sizes and specifications, enabling manufacturers to meet the diverse needs of their clients.

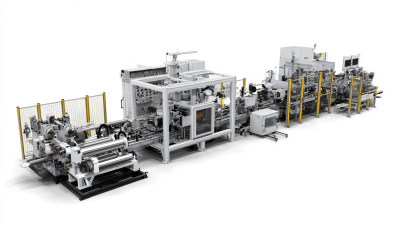

Moreover, the efficiency of custom tube mills is enhanced through advanced technology integration. Automated control systems and real-time monitoring allow for precise adjustments during the manufacturing process, reducing material waste and maximizing output. A study published in the Journal of Manufacturing Processes highlights that advanced manufacturing technologies can improve production efficiency by up to 30%. This is particularly crucial in today's fast-paced market where minimizing downtime and optimizing operations directly correlates with profitability. Companies investing in such advanced machinery position themselves as leaders in quality and responsiveness, ultimately driving business growth in a competitive landscape.

Investing in custom tube mill pipe making machinery offers significant benefits that can enhance your business's operational efficiency. According to industry reports, businesses that adopt customized machinery see an average productivity increase of 20-30%. This uptick is primarily attributed to machinery tailored to specific production needs, which optimizes performance and minimizes downtime. Additionally, custom machinery often integrates advanced technology and automation, leading to improved product quality and reduced labor costs. A study by the National Association of Manufacturers indicates that companies leveraging automation can witness labor cost reductions of up to 25%.

Tips: When selecting custom machinery, ensure it aligns with your production specifications. Conduct a thorough needs assessment to identify the features that will most benefit your operations. Collaborating with machinery designers can facilitate the development of equipment that precisely matches your workflow.

Beyond productivity, custom machinery can significantly decrease material waste and energy consumption. Reports from the Manufacturing Institute suggest that optimized machinery can reduce waste by as much as 15%, a substantial figure considering the rising costs of raw materials. Moreover, energy-efficient custom equipment can lead to energy savings of around 20%. Investing in such technology not only bolsters your bottom line but also fosters sustainable practices within your business.

Tips: Evaluate the long-term savings of energy-efficient machinery against the initial investment costs. Always consider return on investment (ROI) when planning upgrades to your equipment.

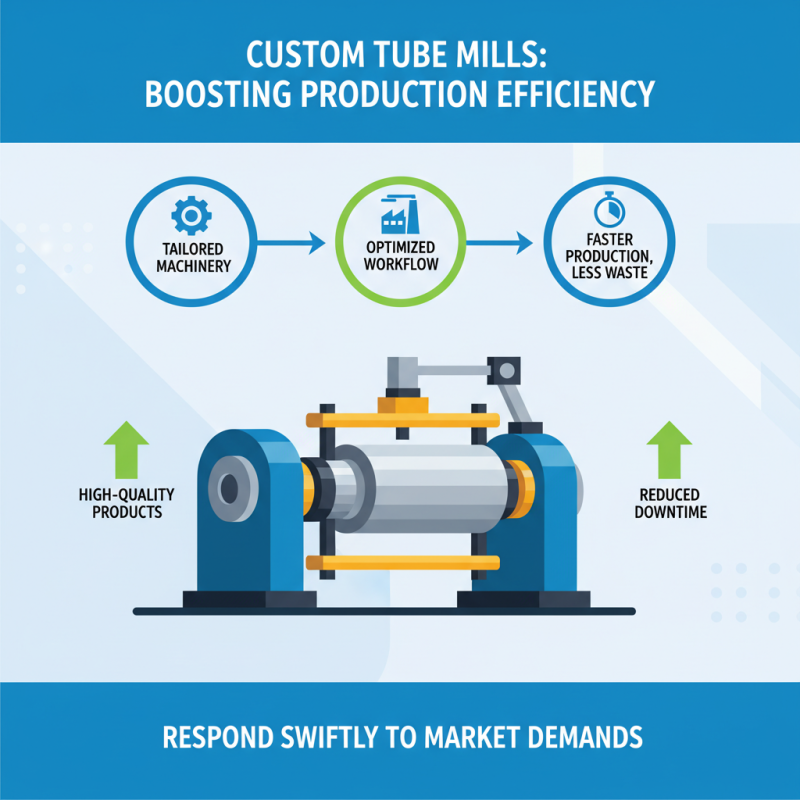

Custom tube mills are designed to enhance production efficiency by streamlining the manufacturing process of pipes and tubes. By employing specialized machinery tailored to specific production needs, companies can optimize their workflows. This customization enables manufacturers to produce high-quality products at a faster pace, reducing downtime and minimizing waste. As a result, businesses can respond more swiftly to market demands, which is crucial in today’s fast-paced industrial environment.

Moreover, custom tube mills facilitate intricate configurations and shapes that would be challenging to achieve with standard equipment. This flexibility allows for innovation in product design, enabling manufacturers to offer a broader range of products to their customers. By improving precision and accuracy in the manufacturing process, custom tube mills not only enhance the quality of the final product but also contribute to cost savings in raw materials and labor. Ultimately, investing in this specialized machinery translates to significant competitive advantages in terms of efficiency, product variety, and overall operational effectiveness.

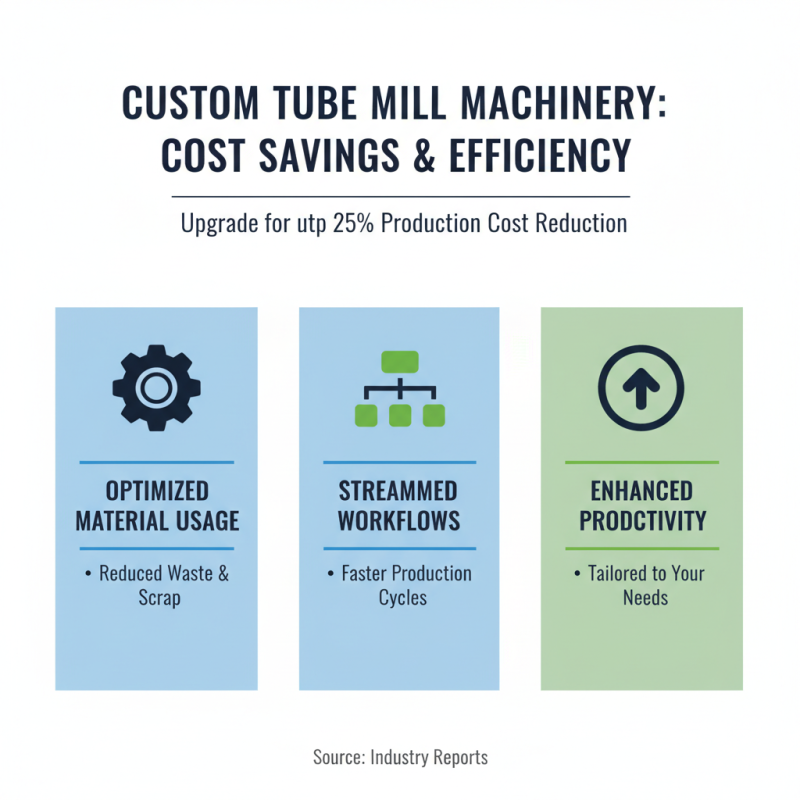

Investing in custom tube mill pipe making machinery presents significant cost-saving opportunities for businesses in the manufacturing sector. According to industry reports, companies that upgrade to customized machinery can reduce production costs by up to 25%. This is primarily attributed to the efficiency gains realized from equipment that is specifically designed to meet the unique needs of the production process. Custom tube mills enable manufacturers to optimize material usage, streamline workflows, and minimize waste, leading to enhanced overall productivity.

Furthermore, the long-term financial benefits of investing in such machinery are highlighted in a recent market analysis, which indicates that companies can recover their initial investments within a short timeframe—often within 18 to 24 months. By decreasing labor costs and increasing throughput, custom tube mills allow businesses to scale their operations without a corresponding rise in expenses. As manufacturers face rising material costs and increased competition, these efficiency improvements can be the difference between sustaining profitability and losing market share. Continual advancements in technology ensure that custom solutions remain at the forefront, ultimately driving down costs and improving the overall bottom line for manufacturers ready to take the leap.

When selecting a custom tube mill for your production needs, it is essential to consider factors that directly impact your operational efficiency. A recent report by the Manufacturing Institute revealed that optimizing machinery can lead to a productivity increase of up to 25%. Therefore, choosing the right custom tube mill not only requires an understanding of the types of materials you will be working with but also the specific dimensions and shapes of the pipes you intend to produce. Customizations can involve the configuration of rolls, welding processes, and specific tooling designs tailored to enhance the finished product's quality.

Furthermore, investment in the right machinery can also reduce operational costs. Data from the Metalworking Industry report indicates that manufacturers who utilize advanced tube mills report a 20% reduction in waste during production compared to those using conventional machines. Focusing on the right specifications and performance features — such as speed, precision, and the ability to handle various material grades — is crucial in maximizing efficiency and achieving optimal yield. Therefore, investing in a tailored tube mill that meets the specific demands of your production line can significantly elevate your business's overall performance and competitiveness in the market.

| Feature | Description | Benefits |

|---|---|---|

| Automation Level | High degree of automation with programmable controls. | Reduces labor costs and enhances precision. |

| Production Speed | Capable of producing up to 300 meters per minute. | Increases throughput and meets high-demand quotas. |

| Material Compatibility | Supports a variety of materials like stainless steel and aluminum. | Versatile for different market needs and applications. |

| Maintenance | Designed for easy access to components for quick maintenance. | Minimizes downtime and prolongs machinery lifespan. |

| Customizability | Can be tailored to specific product dimensions. | Meets unique production requirements of clients. |

| Energy Efficiency | Optimized for lower energy consumption during operations. | Reduces operational costs and environmental impact. |