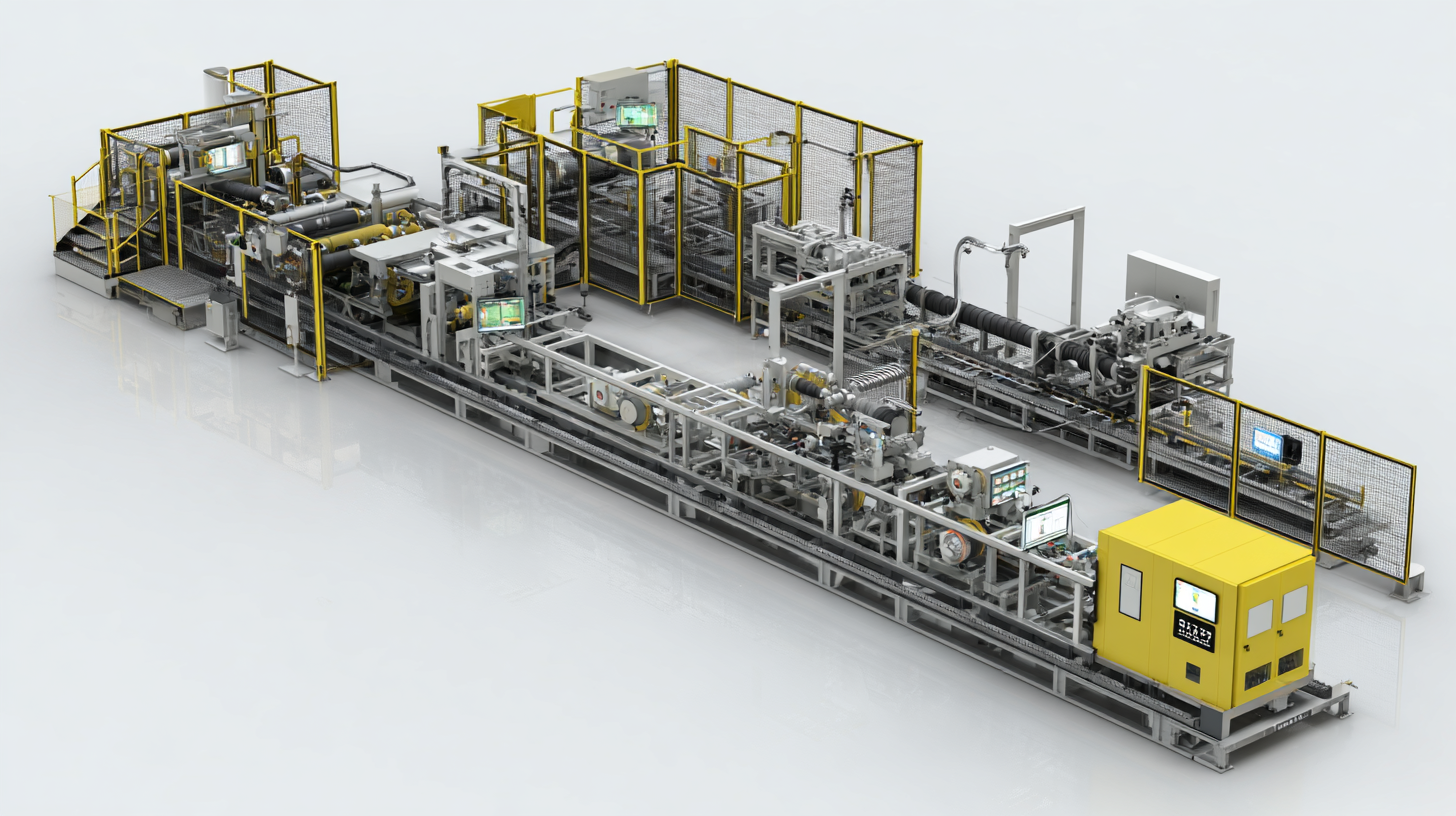

In the rapidly evolving landscape of manufacturing, cost efficiency and operational excellence are paramount, especially when it comes to the maintenance of advanced machinery such as the Industrial Automation Carbon Steel Pipe Making Machine. According to a recent report by the International Federation of Robotics, global spending on industrial automation is expected to exceed $200 billion by 2025, highlighting the increasing reliance on automated systems to streamline production. However, as manufacturers adopt these state-of-the-art machines, the emphasis on after-sales support and maintenance costs becomes critical. Data indicates that maintenance-related expenses can account for nearly 15-20% of total plant operating costs, thus implementing effective optimization strategies can lead to significant financial savings. This blog will explore best practices for minimizing these costs while maximizing the operational lifespan and performance of Industrial Automation Carbon Steel Pipe Making Machines, ensuring manufacturers remain competitive in a demanding market.

Optimizing after-sales support costs in the carbon steel pipe manufacturing sector is vital, particularly as companies navigate increasing operational expenses due to global economic pressures and regulatory changes. According to various industry reports, the average after-sales service cost can account for 10-15% of total production expenses. Implementing strategies such as proactive maintenance schedules and leveraging technology for remote diagnostics can significantly reduce these costs. For instance, predictive maintenance can decrease machine downtime by as much as 20%, which directly correlates to lower support costs.

Additionally, the rise in tariffs on steel imports has further strained the manufacturing industry. By analyzing the financial impact of increased tariffs, companies can make informed decisions regarding their after-sales service models. Investing in low-carbon solutions and streamlining supply chains is essential for maintaining competitiveness in these challenging times. Reports indicate that targeted investments towards emissions reduction can yield substantial cost savings, potentially achieving up to $30 billion in cash flow from lower-emission projects between 2025-2030. This ongoing shift not only supports compliance with environmental regulations but also paves the way for more efficient manufacturing processes, ultimately leading to reduced after-sales support costs.

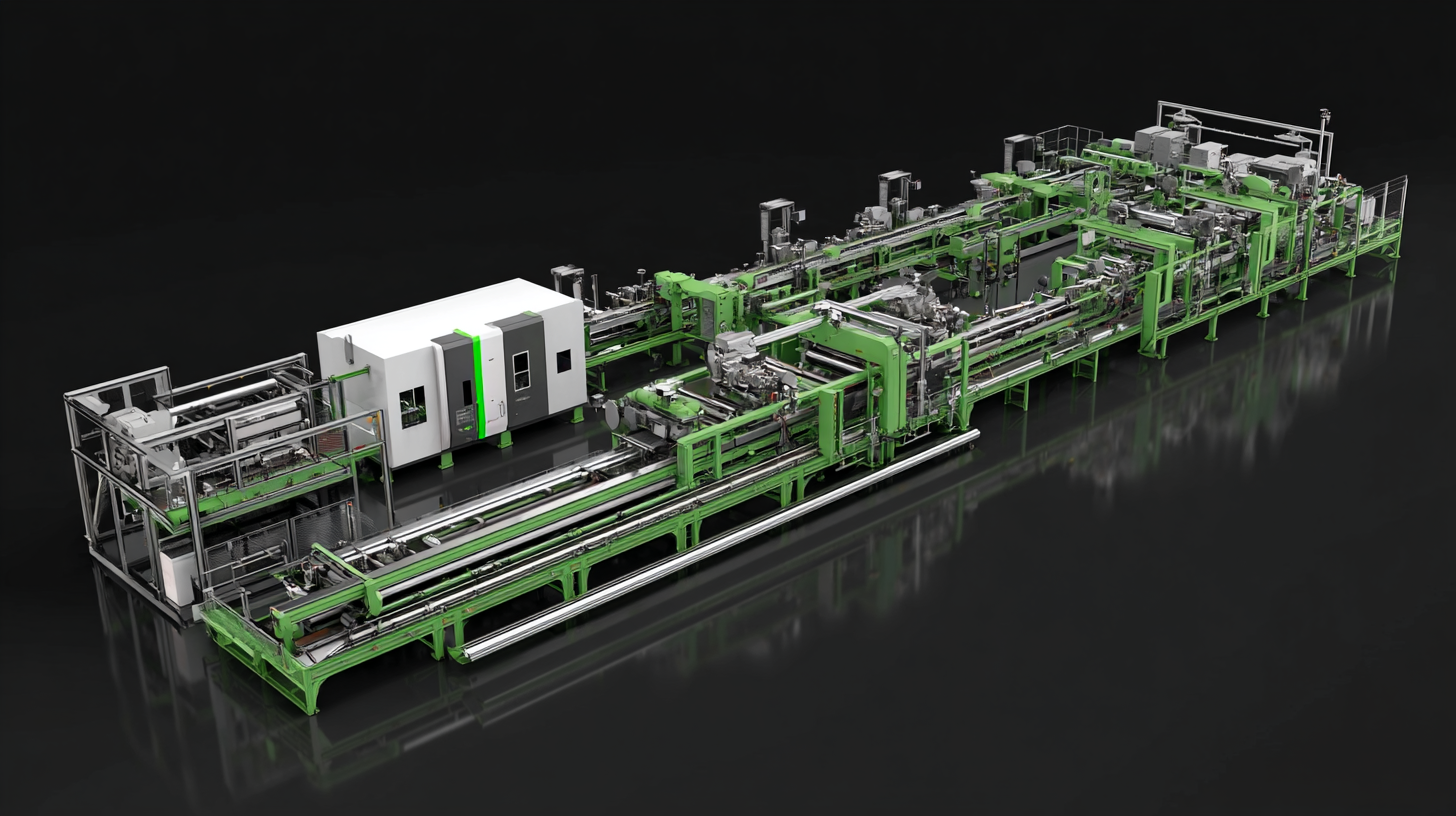

Innovative maintenance techniques are crucial for maximizing the longevity of industrial automation systems, particularly in the production of carbon steel pipes. As companies increasingly adopt predictive maintenance strategies, leveraging advancements in technologies like artificial intelligence and the Internet of Things (IoT) has become essential. According to recent industry reports, predictive maintenance can reduce typical maintenance costs by up to 30% while improving equipment uptime significantly.

Implementing AI-driven analytical tools allows for real-time monitoring of machine performance, enabling timely interventions before potential failures occur. This proactive approach is complemented by new methodologies in maintenance, such as condition-based monitoring, which assesses the health of machinery continually rather than relying on scheduled checks. A 2023 study highlighted that companies employing these innovative maintenance techniques saw a 50% reduction in unplanned downtimes, an impressive statistic that illustrates the profound impact these methods can have on operational efficiency.

Furthermore, integrating advanced sensor technologies within machines provides valuable data that can be used to fine-tune operations, optimize workflows, and ultimately extend machinery life. By focusing on these innovative maintenance solutions, businesses not only enhance their production processes but also reduce the overall lifecycle costs associated with their carbon steel pipe making machines.

In the realm of industrial automation, the significance of after-sales support cannot be overstated, particularly for complex machinery like carbon steel pipe making machines. Leveraging data analytics can dramatically enhance the efficiency of after-sales service, ensuring that customers receive the best support possible. By harnessing real-time data from machines, companies can monitor performance and predict maintenance needs, thereby reducing downtime and optimizing service schedules.

Data analytics allows organizations to identify recurring issues and trends in machine performance, enabling technicians to address problems proactively rather than reactively. This shift from a traditional support model to a data-driven approach ensures that resources are allocated efficiently. Moreover, machine learning algorithms can analyze vast amounts of service history data, allowing for tailored training programs for service teams, ensuring they are equipped to handle specific customer needs effectively. By implementing these strategies, companies not only save on maintenance costs but also enhance customer satisfaction and loyalty.

Training support teams in the industrial automation sector is crucial for optimizing after-sales support and maintenance costs. A well-trained support team can significantly reduce downtime and enhance customer satisfaction, particularly for complex machinery such as carbon steel pipe making machines. To achieve this, it is essential to implement a structured training program that covers both technical and soft skills. Technical training should focus on the specific machinery, troubleshooting procedures, and maintenance best practices, enabling support staff to address issues efficiently.

Additionally, soft skills training is equally important as it equips support teams to communicate effectively with clients. Effective communication enhances the ability to understand client concerns and provide personalized solutions. Role-playing scenarios and simulation exercises can be beneficial in developing these skills. Regular workshops and feedback sessions can further reinforce learning, allowing teams to adapt and update their knowledge as new technologies and methods emerge in industrial automation.

By investing in comprehensive training for support teams, companies can ensure a proactive approach to maintenance and support, ultimately leading to reduced costs and improved overall performance.

Emerging technologies are playing a pivotal role in revolutionizing the maintenance solutions for industrial automation, particularly in the realm of carbon steel pipe making machines. One of the most promising advancements is the integration of IoT (Internet of Things) sensors, which can monitor equipment performance in real-time. By collecting data on key operational parameters, these sensors enable predictive maintenance strategies. This approach helps in anticipating potential failures before they occur, thereby reducing unplanned downtime and maintenance costs significantly.

Additionally, the adoption of AI (Artificial Intelligence) and machine learning algorithms further enhances maintenance efficiency. These technologies can analyze historical data to identify patterns and optimize maintenance schedules accordingly. By leveraging AI, manufacturers can move from a reactive maintenance model to a more proactive one, ensuring that servicing is performed at the most opportune time, which minimizes disruptions to production and extends the lifespan of machinery. Ultimately, embracing these emerging technologies not only leads to cost-effective maintenance solutions but also positions companies to enhance overall productivity and competitiveness in the industrial automation landscape.