In today's competitive manufacturing landscape, optimizing production efficiency is paramount, especially in the metalworking industry. The adoption of an Industrial Automation Carbon Steel Pipe Making Machine is a strategic approach that can significantly enhance production capabilities. According to a report by MarketsandMarkets, the global industrial automation market is projected to reach $295 billion by 2026, with a compound annual growth rate (CAGR) of 9.2%. This growth signals a clear shift towards automation to meet growing demand while reducing operational costs. With the ability to streamline processes, minimize human error, and improve product quality, integrating automated solutions into the pipe manufacturing sector can lead to substantial productivity gains. As industries continue to embrace digitalization, understanding how to effectively implement and utilize an Industrial Automation Carbon Steel Pipe Making Machine becomes crucial for staying ahead in the market.

In the evolving landscape of pipe manufacturing, industrial automation plays a pivotal role in enhancing production efficiency and quality. With advancements in technology, manufacturers are increasingly investing in automated systems that streamline workflows, reduce labor costs, and ensure consistent product quality. A recent study highlighted the significance of statistical process control (SPC) as a crucial tool for managing quality, allowing companies to monitor and optimize their manufacturing processes effectively. By leveraging automation, entities can achieve real-time data collection and analysis, which empowers decision-making and helps in immediate troubleshooting of any production issues.

The establishment of new manufacturing facilities around the globe, such as the recent investments in North America and Asia, reflect the industry's shift towards high-precision production methods. Notably, the construction of a seamless pipe manufacturing facility in Southeast Asia marks a significant milestone for regional manufacturing capabilities, showcasing the growing demand for sophisticated production solutions. Additionally, investments in automation technologies enable facilities to enhance throughput and achieve better resource management, illustrating how modernized systems are redefining standards in pipe manufacturing. As industry leaders prioritize automation, it is evident that integrating advanced technology into production lines will remain a critical strategy for maintaining competitive advantage in the market.

When selecting a carbon steel pipe making machine, it's essential to consider key features that enhance productivity and ensure high-quality output. One of the most significant aspects is the machine's ability to accommodate various pipe sizes and wall thicknesses, which can greatly impact the versatility of production. A machine with adjustable parameters allows manufacturers to switch between different pipe specifications without significant downtime, making it an efficient choice for dynamic production lines.

Another critical feature is the integration of advanced automation technologies. Machines equipped with smart sensors and machine learning algorithms can optimize the production process by predicting maintenance needs and identifying potential faults before they lead to significant production halts. This not only enhances operational efficiency but also helps in reducing the overall machinery costs over time, aligning with current industry trends towards sustainable and responsible manufacturing practices.

Additionally, features that facilitate easy maintenance and operator training can significantly contribute to minimizing operational disruptions, making the investment in such machinery worthwhile for manufacturers looking to streamline their production lines in an increasingly competitive market.

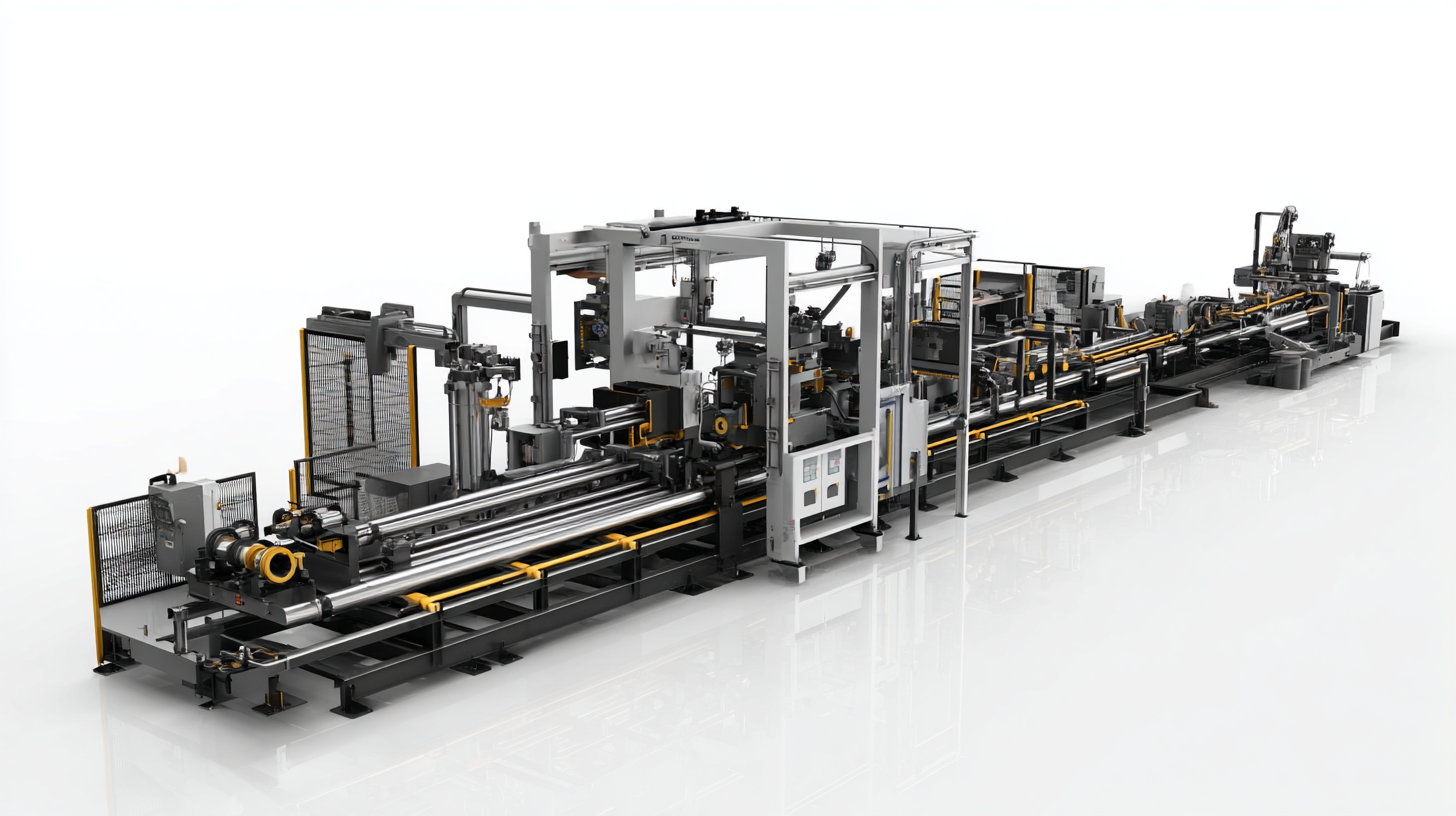

Optimizing the layout of your production line is essential for enhancing efficiency and maximizing output when using an industrial automation carbon steel pipe making machine. A well-planned layout minimizes unnecessary movement, reduces material handling time, and streamlines the workflow. By employing techniques such as the cellular manufacturing layout, you can group machines and workstations based on product families, which facilitates smoother transitions and reduces bottlenecks.

Another effective strategy is to utilize a linear layout for your production line. This design allows for a sequential flow of materials and components, which is particularly beneficial in environments where the production process requires multiple steps. Integrating automation components like conveyors and robotic arms can further enhance the workflow, allowing for synchronized operations that keep pace with production demands. Regularly reviewing and adjusting the layout in response to changing workflows or production volumes will ensure that the system remains effective over time, ultimately leading to increased productivity and reduced lead times.

| Parameter | Description | Optimized Value | Industry Standard |

|---|---|---|---|

| Production Speed | Rate of production per hour | 120 pipes/hour | 100 pipes/hour |

| Waste Rate | Percentage of materials wasted | 3% | 5% |

| Setup Time | Time taken to set up machinery | 30 minutes | 60 minutes |

| Downtime | Total hours of production halted | 2 hours/week | 5 hours/week |

| Labor Efficiency | Output per labor hour | 50 pipes | 35 pipes |

Regular maintenance and proper operation of your industrial automation carbon steel pipe making machine are crucial for maximizing efficiency and reducing downtime. First, it’s essential to establish a routine maintenance schedule that includes inspecting all mechanical components for wear and tear, checking lubrication levels, and ensuring that the electrical systems are functioning properly. This proactive approach can help identify potential issues before they escalate into costly repairs.

Tip: Always keep a maintenance log to track inspections, repairs, and part replacements. This record will aid in identifying patterns and improving your maintenance strategy over time.

In addition to maintenance, effective operation practices can significantly enhance the performance of your pipe making equipment. Train your operators thoroughly on the machine’s functions and limitations. Educate them on optimal settings, which can vary based on the material and pipe specifications. Encouraging a culture of safety and attentiveness will also reduce accidents and promote a more efficient workflow.

Tip: Implement a ‘stop and fix’ policy where operators are empowered to pause production if they notice any irregularities, ensuring that small issues are addressed promptly before they escalate.

To achieve optimal efficiency in your production line with an industrial automation carbon steel pipe making machine, measuring key performance indicators (KPIs) is essential. KPIs such as Overall Equipment Effectiveness (OEE), production yield, and cycle time can provide valuable insights into your operation’s efficiency. According to a report by the Manufacturing Performance Institute, companies that closely monitor their KPIs can experience a 20% increase in productivity.

**Tips:** Regularly conduct maintenance and upgrades on your machinery to ensure it runs at its full potential. For instance, aligning your equipment maintenance schedule with production goals can help you identify bottlenecks and reduce downtime.

Another crucial indicator is the Rate of Return on Investment (ROI). A well-implemented industrial automation system can lead to a significant decrease in labor costs—up to 30%, as per industry estimates—allowing for reinvestment into further technological advancements. Tracking these financial metrics not only informs your decision-making but also highlights areas where efficiency gains can be maximized.

**Tips:** Benchmark your operation against industry standards to identify areas for improvement. Utilizing data analytics tools can provide deeper insights into performance trends and assist in maintaining competitiveness in the market.