In today’s fast-paced manufacturing environment, optimizing the production line is essential for maintaining efficiency and competitiveness. One of the key components in achieving this goal is the use of advanced equipment, such as the Pipe Making Machinery Tube Mill. This specialized machinery plays a crucial role in streamlining the production of pipes and tubes, ensuring that manufacturers can produce high-quality products at a rapid pace. By understanding the various types of Pipe Making Machinery Tube Mills available, businesses can make informed decisions that enhance their manufacturing processes. This article aims to explore the different categories of tube mills, their functions, and how they contribute to optimizing production lines, thereby providing valuable insights for manufacturers looking to improve their operations and meet market demands effectively.

Pipe making machinery, particularly tube mills, plays a critical role in the manufacturing sector, enabling efficient production of high-quality pipes for various applications. According to a recent report by MarketsandMarkets, the global tube mill market is projected to reach USD 4.5 billion by 2025, growing at a CAGR of 5.4%. This growth is driven by the increasing demand in construction, automotive, and energy sectors, where durable and reliable piping solutions are essential.

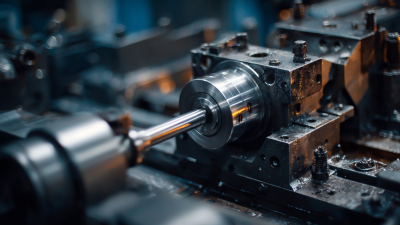

Understanding the functionality of tube mills is pivotal for optimizing your production line. These machines are designed to manufacture pipes by continuously rolling flat steel strips into a tubular shape and welding the edges. Advanced tube mills incorporate features such as automatic welding and precision forming, which enhance productivity and reduce material waste. A study from the International Journal of Mechanical Engineering & Technology highlighted that implementing high-frequency welding technology can improve production efficiency by up to 25%, emphasizing the importance of adopting modern tube mill innovations to stay competitive in a rapidly evolving industry.

The efficiency of a tube mill system is greatly influenced by its key components, which include the entry section, forming section, welding section, sizing section, and cutoff section. According to a report by Market Research Future, the global tube mill market is expected to grow at a CAGR of 6.2% from 2021 to 2027, driven by advancements in machinery and increasing demand in various industries such as automotive and construction. Each component plays a critical role in ensuring a seamless production flow, significantly impacting both output and product quality.

The forming section, for example, utilizes adjustable rollers to shape the metal strip accurately into a tube, emphasizing the importance of precision in the manufacturing process. Similarly, modern welding systems have evolved to deliver faster and more reliable welds, with some systems achieving speeds of up to 600 feet per minute. Data from the Steel Tube Institute highlights that investments in high-speed tube mills can lead to a reduction of manufacturing time by up to 30%, allowing producers to respond quickly to market demand. Therefore, optimizing these components not only enhances the production capacity but also minimizes waste and operational costs, ultimately leading to greater competitiveness in the tube manufacturing industry.

Optimizing production lines with modern pipe making technology can significantly enhance operational efficiency and reduce costs. According to a report by Industry Insights, companies that have integrated advanced pipe making machinery, such as tube mills, have reported a productivity increase of up to 25%. This increase is attributed to reduced machine downtime and faster production cycles, allowing manufacturers to respond more quickly to market demands.

To maximize these benefits, implement regular maintenance schedules for your machinery. Well-maintained tube mills can function more reliably and efficiently, thereby preventing costly interruptions. Additionally, consider investing in automation technologies that streamline the entire production process. A study by Manufacturing Technology recently found that automated systems can decrease labor costs by 30% while improving product consistency and quality.

Tips: One effective strategy is to conduct a thorough analysis of your current production workflows. Identifying bottlenecks can lead to targeted improvements. Moreover, training your workforce to adeptly handle new technology ensures that you are leveraging your investments to their fullest potential, leading to a more agile production line.

Optimizing your production line with pipe making machinery, specifically tube mills, is crucial for enhancing efficiency and product quality. Implementation strategies focus on adopting best practices in tube mill performance. A recent industry report from Grand View Research indicates that the global market for welded pipes is expected to reach $76.57 billion by 2025, highlighting the increasing demand for optimized production processes.

To enhance tube mill performance, one of the key strategies is regular maintenance and calibration of machinery. This ensures optimal operating conditions and reduces the risk of downtime. According to a study by the Machinery Institute, companies that implement a proactive maintenance strategy can reduce equipment failure rates by up to 30%.

Tips: Invest in training your staff on the latest operating techniques and technologies. This not only boosts productivity but also fosters a culture of continuous improvement. Additionally, utilizing advanced monitoring systems can provide real-time data analytics, enabling quick adjustments to maintain peak performance levels. Implementing these strategies can significantly increase the overall efficiency of your tube mill operations.

When operating a tube mill, various challenges can impede productivity and efficiency. Common issues include inconsistent material quality, equipment wear, and inefficient water management. These problems often lead to increased downtime and reduced output.

To tackle these challenges, it's essential to adopt advanced solutions that enhance operational integrity. For example, implementing a closed-circuit process water management system can optimize water usage and maintain consistent quality in manufacturing processes, thereby minimizing waste and improving product reliability.

Moreover, demand-driven tap water distribution within the facility can further streamline operations. By ensuring an efficient supply of water when needed, tube mills can enhance cooling and cleaning processes, which are critical for maintaining the longevity of machinery and product quality. Additionally, addressing wastewater solids through effective eradication techniques can prevent clogging and equipment malfunctions, thereby maintaining a smooth workflow. By focusing on these solutions, tube mills can significantly improve their production line efficiency and overcome common operational hurdles.