In the rapidly evolving landscape of manufacturing, the integration of advanced technologies into the Pipe Welding Machine Tube Mill Production Line is poised to revolutionize traditional processes. As industries seek to enhance efficiency and precision, the role of innovative welding machines becomes paramount, propelling production capabilities to new heights. This article delves into the transformative impact of digitalization on manufacturing, particularly focusing on the advancements in pipe welding technology. From automation and real-time monitoring to data analytics and machine learning, the future of pipe welding in tube mill production lines is not just about speed but also about achieving unprecedented levels of quality and reliability. By adopting these state-of-the-art machines, manufacturers can optimize their operations, reduce waste, and meet the ever-increasing demands for high-quality products in a competitive market. Join us as we explore essential tips and insights that highlight the pivotal role of pipe welding machines in shaping the future of manufacturing.

The role of pipe welding machines in modern tube mill production lines is pivotal in ensuring efficiency and precision. These machines are designed to handle various materials and sizes, adapting to the specific requirements of different production processes. Advanced technologies, such as laser welding and robotic automation, are increasingly integrated into pipe welding systems. This transition not only enhances productivity but also significantly improves weld quality, ensuring stronger and more reliable tube structures that meet stringent industry standards.

Furthermore, the modernization of pipe welding machines contributes to a more sustainable manufacturing process. With better energy management and reduced material waste, manufacturers can achieve higher environmental compliance while maintaining output efficiency. As companies strive for greater competitiveness in global markets, the ability to quickly adapt to changing demands with advanced welding technology becomes a critical factor. The evolution of these machines illustrates a broader trend towards innovation in manufacturing, where precision engineering meets the need for high-quality production capabilities in the tube and pipe industry.

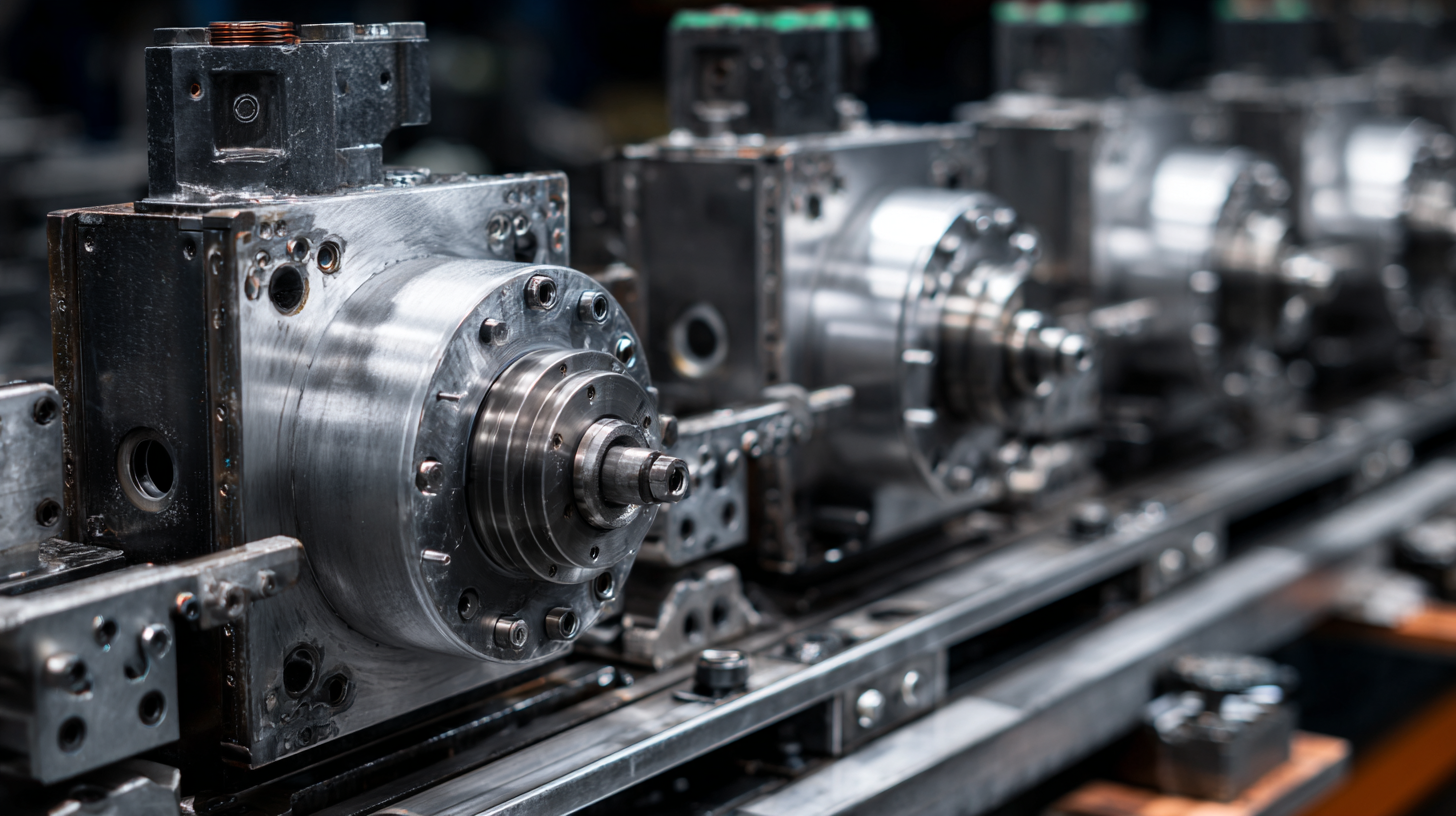

The pipe welding industry is undergoing a transformational shift driven by key technologies that enhance efficiency and precision in tube mill production lines. According to a report by MarketsandMarkets, the global market for automated welding machines is projected to reach $9.47 billion by 2026, growing at a CAGR of 6.4%. This growth is propelled by advancements such as laser welding, which offers superior speed and quality over traditional methods. Laser welding systems in pipe manufacturing provide seamless joints and reduce the heat-affected zone, resulting in less distortion and improved structural integrity.

Additionally, the integration of Industry 4.0 technologies, including the Internet of Things (IoT) and artificial intelligence (AI), is revolutionizing how pipe welding machines are operated and maintained. IoT-enabled sensors allow for real-time monitoring of welding parameters, which can significantly minimize downtime and optimize production. A study by Deloitte highlights that manufacturers adopting smart technologies can expect a productivity increase of up to 30% within five years. Moreover, AI-driven algorithms can analyze vast amounts of welding data to identify patterns and predict failures, further enhancing operational efficiency and reducing costs. This convergence of innovative technologies signals a promising future for the pipe welding sector in manufacturing.

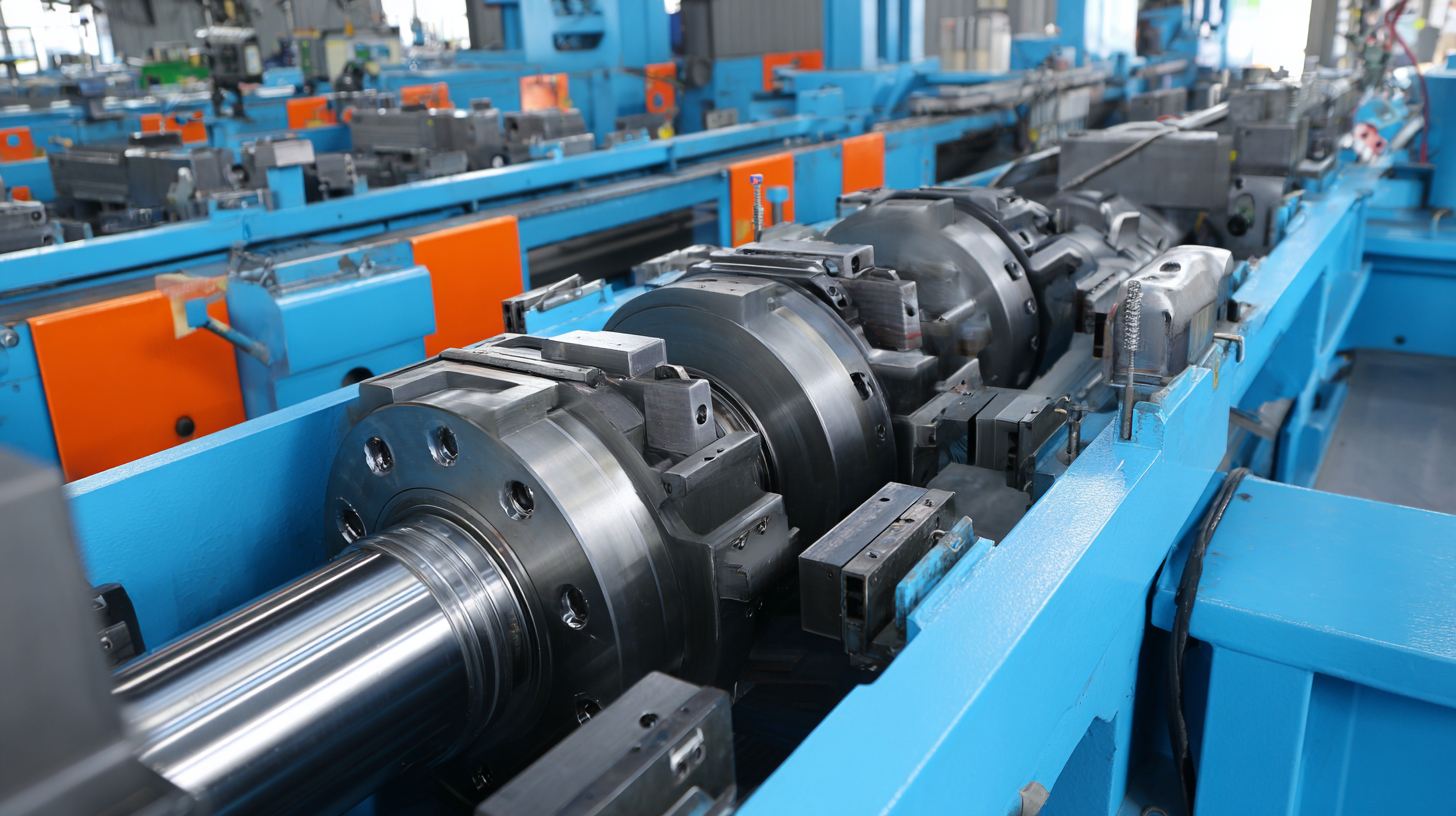

As manufacturing processes evolve, optimizing tube mill production lines has never been more critical. Advanced welding techniques, particularly in pipe welding machines, play a substantial role in enhancing efficiency and quality. According to a recent industry report, implementing automated welding systems can increase production efficiency by up to 30%, while also improving the consistency and strength of welds. By adopting such technologies, manufacturers can significantly reduce downtime and costs associated with manual welding processes.

To maximize the benefits of advanced welding techniques, it is essential to focus on employee training and machine maintenance. Regular training ensures that operators are familiar with the latest welding technologies and practices, which can lead to fewer errors and defects. Additionally, investing in routine maintenance of welding machines can prevent unexpected breakdowns, contributing to smoother operations and extended equipment lifespan.

Tip: Consider integrating predictive maintenance solutions that utilize IoT sensors to monitor equipment performance. These systems can alert operators before a malfunction occurs, ensuring optimal uptime and production efficiency. By leveraging data analytics alongside advanced welding techniques, tube mills can position themselves at the forefront of the manufacturing revolution.

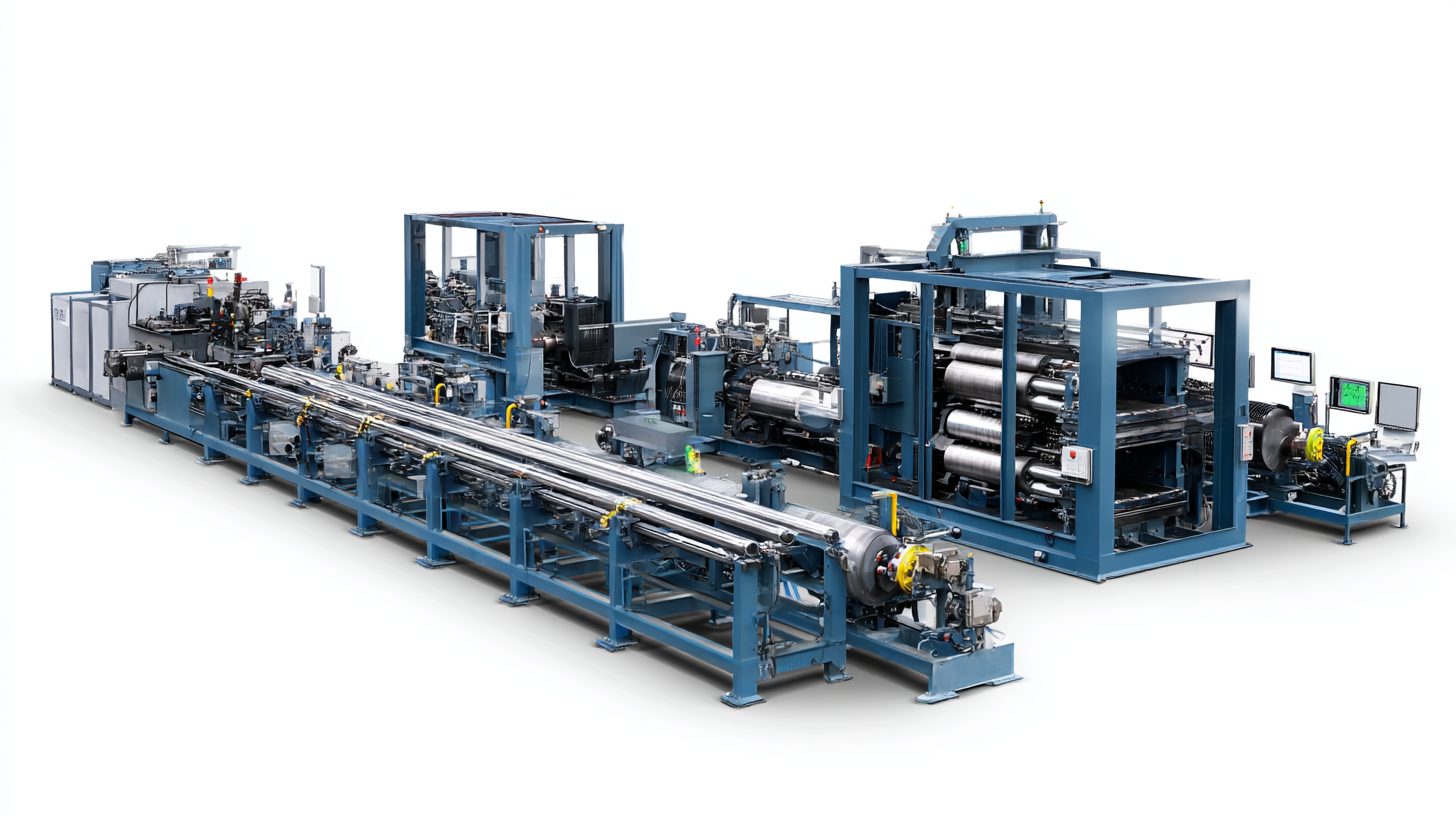

The integration of automation in pipe welding machines is ushering in a new era of efficiency and precision for tube mill production lines. As manufacturers strive to meet increasing demand while maintaining quality, automated welding processes are becoming essential. By employing advanced robotics and intelligent software systems, these machines can perform complex welding tasks with minimal human intervention, significantly reducing the potential for errors. This transition not only accelerates production rates but also ensures consistent weld quality, which is critical for the integrity of welded pipes.

Moreover, the implementation of automated systems in pipe welding machines allows for real-time monitoring and data collection. This capability enables manufacturers to analyze performance metrics, predict maintenance needs, and optimize operations. As a result, companies can reduce downtime and operational costs while enhancing overall productivity. The future of welding in tube mills lies in the ability to integrate cutting-edge technology, transforming traditional methods into streamlined processes that meet modern industrial demands. This shift not only benefits manufacturers but also contributes to the sustainability of manufacturing practices by minimizing waste and energy consumption.

The future of pipe welding machines is poised for significant transformation, driven by innovations that prioritize sustainable manufacturing practices. As industries seek to reduce their environmental footprint, advancements in machine efficiency and material usage are becoming increasingly paramount. The integration of lightweight composite structures into manufacturing processes can enhance welding techniques, allowing for greater strength and durability while minimizing resource waste. This aligns with broader manufacturing trends focusing on sustainability and the circular economy, which advocate for the reuse and recycling of materials.

Moreover, the rise of additive manufacturing technologies, particularly in the context of 3D printing, is anticipated to reshape pipe welding in tube mill production lines. These innovations not only streamline production processes but also enable manufacturers to create complex geometries that were previously impossible. With an emphasis on customized solutions and on-demand production, companies can significantly cut down on inventory costs and reduce excess material use. As we look towards 2025 and beyond, the adoption of these advanced technologies will be crucial in establishing a sustainable framework for the future of manufacturing, particularly in the realm of pipe welding.