The 137th Canton Fair, held in Guangzhou, has set a new benchmark in international trade by attracting an unprecedented number of overseas buyers, with 288,938 attendees from 219 countries, reflecting a 17.3% increase compared to the previous session. Within this dynamic environment, manufacturers of High Frequency Pipe Welding Machines showcased their cutting-edge innovations, capitalizing on the fair's substantial export potential, which reached $25.44 billion, up 3% from the last event. As demand for efficient and technologically advanced welding solutions continues to rise globally, the fair provided a crucial platform for key players in the industry to network and expand their reach.

The ongoing online platform also ensures that transactions and interactions persist beyond the physical event, highlighting the significance of High Frequency Pipe Welding Machines in contemporary manufacturing processes. As we look forward to the upcoming 138th Canton Fair, the visibility and opportunities for these specialized machines are poised to further enhance their market presence and meet the evolving needs of the industrial sector.

The 137th Canton Fair, renowned as one of the largest trade fairs globally, has showcased the latest innovations in various industries, including the booming sector of high-frequency pipe welding machines. With the increasing demand for efficient and high-quality welding solutions, manufacturers from China are stepping up to meet the global market's needs. According to a report by ResearchAndMarkets, the global pipe welding market is expected to reach $20 billion by 2025, fueled by advancements in technology and rising infrastructure projects worldwide. This trend emphasizes the significance of Chinese manufacturers in supplying cutting-edge equipment that adheres to international standards.

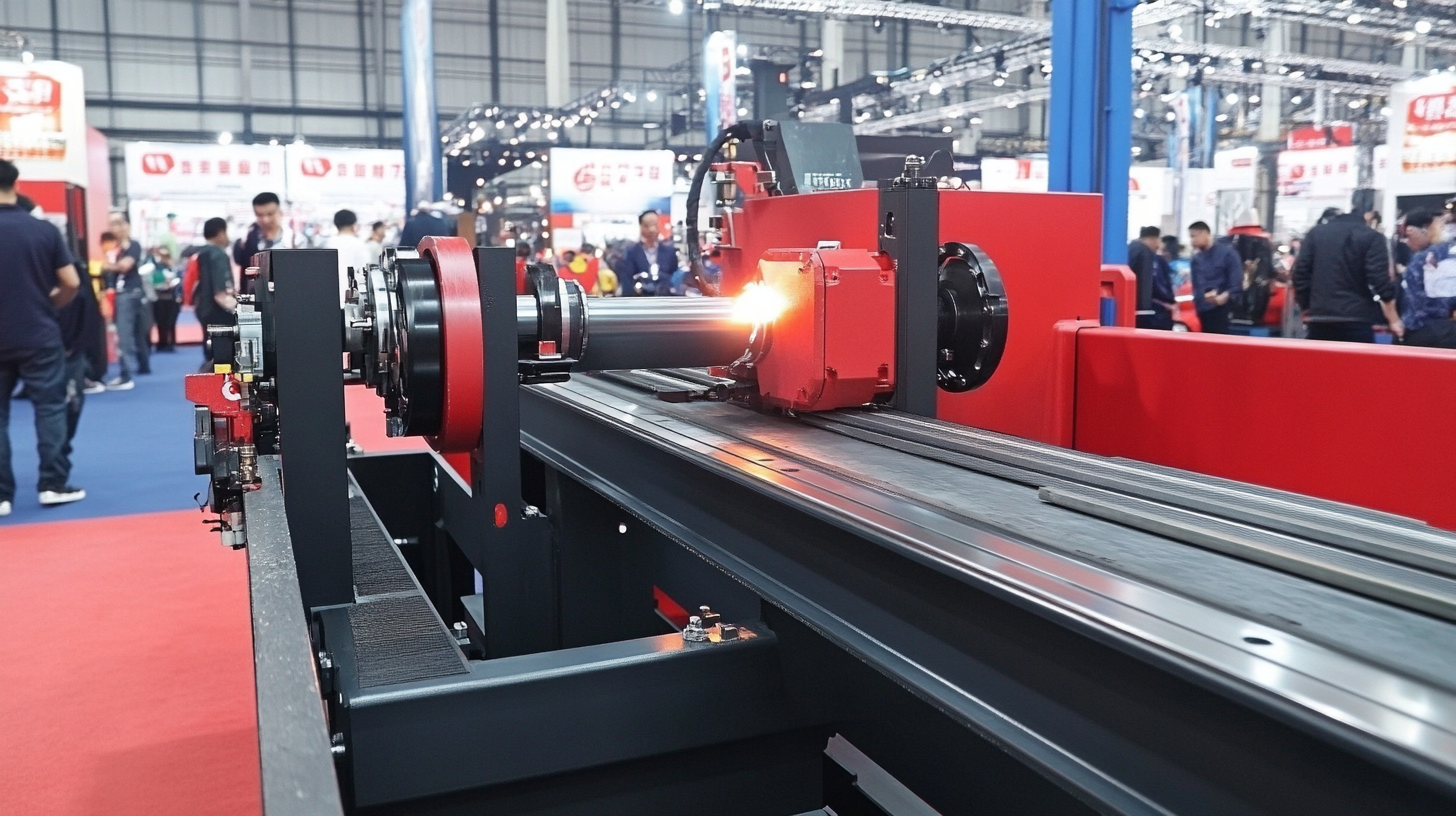

At the Canton Fair, attendees observed a remarkable array of high-frequency pipe welding machines that enhance speed and precision in welding processes. Industry experts noted that these machines not only reduce material wastage but also improve overall productivity, which is critical as industries strive for sustainability and efficiency. The global market for welding equipment is projected to grow at a CAGR of 5.5% from 2021 to 2026, as highlighted by the Global Market Insights report. The presence of leading manufacturers at the fair illustrates China's pivotal role in shaping trends and influencing global trade, providing a unique platform for collaboration and innovation among industry players.

The 137th Canton Fair showcased an impressive array of high frequency pipe welding machines, highlighting advancements in technology and manufacturing capabilities. Exhibitors presented a diverse range of models, each featuring unique specifications catering to various industries, from construction to shipbuilding. Notable brands demonstrated innovations in speed, energy efficiency, and precision, capturing the attention of international buyers and industry experts alike. These machines not only enhance productivity but also provide significant cost savings, making them a valuable investment for businesses aiming to stay competitive.

Among the manufacturers, several stood out for their commitment to quality and performance. Leading companies utilized cutting-edge materials and techniques to ensure durability and reliability in their machines. Additionally, many manufacturers offered customization options, allowing customers to tailor machines according to their specific needs. The fair served as a vital platform for networking and collaboration, as manufacturers engaged directly with potential clients, showcasing their expertise and establishing partnerships for future projects.

The 137th Canton Fair showcased groundbreaking trends in pipe welding technology, reflecting the rapid advancements in the industry. Manufacturers presented state-of-the-art high frequency pipe welding machines, emphasizing increased efficiency and precision. These machines are designed to meet the growing demands of various sectors, from construction to energy, where strong and durable pipe joints are critical. Notably, the integration of automation and smart technology is transforming traditional welding processes, allowing for faster production times and higher quality outputs.

Attendees observed a significant focus on sustainability and energy-saving features in the new equipment. Innovations such as reduced power consumption and environmentally friendly materials are becoming standard expectations among manufacturers. The fair also highlighted the importance of adapting to evolving market needs, encouraging manufacturers to invest in research and development for more versatile welding solutions. This shift not only enhances performance but also supports a more sustainable approach in the pipe welding industry, aligning with global efforts to reduce carbon footprints and promote eco-friendly practices.

The 137th Canton Fair showcased a variety of manufacturers in the high-frequency pipe welding sector, with several emerging companies making notable impressions. The introduction of innovative technologies, such as the on-line spray water cooling (OSWC) system for electric-resistance-welded (ERW) steel pipes, has the potential to redefine manufacturing processes. This system eliminates the need for traditional off-line heat treatment, leading to increased efficiency and reduced production times, making it a game-changer in the high-frequency welding landscape.

Emerging manufacturers at the fair not only highlighted their commitment to advanced production techniques but also emphasized the increasing demand for competitive pricing amidst ongoing challenges. For instance, U.S. manufacturing has been under pressure due to tariffs, which have led to higher input costs and strained supply chains. This scenario intensifies the need for cost-effective solutions and innovative practices in the pipe welding industry. As companies like those featured at the Canton Fair continue to adapt to market demands, we can expect to see significant developments that may reshape the market dynamics in the coming years.

| No | Manufacturer Type | Machine Specifications | Max Pipe Diameter (mm) | Power Source (kW) | Production Capacity (pcs/hr) |

|---|---|---|---|---|---|

| 1 | Automatic | High Frequency Welding, Pulse Control | 300 | 100 | 500 |

| 2 | Semi-Automatic | Real-Time Measurement, PLC Control | 250 | 80 | 350 |

| 3 | Fully Automatic | Integrated Cooling System, Touch Screen Interface | 400 | 120 | 700 |

| 4 | Manual | Basic Welding Features, Compact Design | 200 | 60 | 200 |

| 5 | Mobile | Portable Design, Battery Operated | 150 | 40 | 150 |

| 6 | Heavy Duty | Reinforced Frame, Robust Operation | 450 | 150 | 800 |

| 7 | Industrial | Continuous Welding Process, High Stability | 500 | 180 | 1000 |

| 8 | Desktop | Compact for Small Pipes, Space Saving | 100 | 20 | 100 |

| 9 | Specialized | Customized Solutions for Niche Applications | 350 | 90 | 600 |

| 10 | Custom | Tailored according to Customer Needs | 400 | 150 | 750 |

As the 138th Canton Fair approaches in 2025, industry experts anticipate significant developments within the high-frequency pipe welding sector. This biannual event is renowned for showcasing innovations and facilitating international trade. Market analyses indicate that the high-frequency pipe welding machine market is poised for growth, with a projected compound annual growth rate (CAGR) of 5.7% through 2026, driven by increasing demand in sectors such as construction and manufacturing.

Attendees at the 138th Canton Fair can expect a wide range of advanced technologies and machinery from leading manufacturers. Data from industry reports suggests that China dominates the high-frequency welding machine market, accounting for over 40% of global production capacity, primarily due to its robust supply chain and manufacturing infrastructure. This creates a fertile ground for innovation, with companies focusing on enhancing automation and energy efficiency in their products. Visitors will have the opportunity to explore the latest trends and capabilities that these machines offer, ensuring they remain competitive in an evolving industry landscape.

This bar chart illustrates the estimated production capacity of the top 10 high frequency pipe welding machine manufacturers in China. The capacities are measured in units produced annually, providing insights into the scale of operations for these manufacturers.